Reading A Ruler |

|

Self

Study Program, Self

Study Program,

"Welding Math and Science;" 87 Pages, Part # WMS

This program provides basic information to help

welding students and welding supervisors understand welding process

characteristics using basic math and science. Includes and Appendix with

Simplified Basic Math Functions and Metric Conversions.

CLICK to See Program Details

CLICK for Purchase Page

|

|

Reading a ruler

in US Measurement Units requires working with

Fractions. If the

Metric

System was being used it would not - more on

Metric below.

Rulers and

measuring tapes are commonly calibrated in feet and inches. Instead of

segmenting the foot into 10ths of a foot - it is divided into 12 parts

called inches.

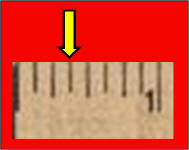

The inch is commonly split into 8, 16 or

sometimes 32 parts. Therefore working with

Fractions is a necessity. A

Fraction of an inch is a mathematical way of showing the number of the parts

into which it is divided. For example, 3/8 inches is a measure

of 3

of the 8 parts. The picture left is an

example of an inch split into 8 parts or "eighths." The yellow arrow is

pointing to the third line from the start or the 3rd of 8 parts stated as

3/8. It’s shown with a division line between the numbers since we could divide 3 by 8 and get

0.375 the decimal value. If we always

stated the number of segments measured and the total number of segments into which

the inch mark was split, Fractions would be relatively easy.

Unfortunately it is not that easy! We'll try to make it as painless as

possible! The inch is commonly split into 8, 16 or

sometimes 32 parts. Therefore working with

Fractions is a necessity. A

Fraction of an inch is a mathematical way of showing the number of the parts

into which it is divided. For example, 3/8 inches is a measure

of 3

of the 8 parts. The picture left is an

example of an inch split into 8 parts or "eighths." The yellow arrow is

pointing to the third line from the start or the 3rd of 8 parts stated as

3/8. It’s shown with a division line between the numbers since we could divide 3 by 8 and get

0.375 the decimal value. If we always

stated the number of segments measured and the total number of segments into which

the inch mark was split, Fractions would be relatively easy.

Unfortunately it is not that easy! We'll try to make it as painless as

possible! |

|

The example on the right shows the 4th of the

1/8 inch marks in red. Since 4 is half way to 8 - it is the 1/2

inch mark. We could have said the 4/8 mark which is the same as saying 1/2 .

It is usually desired to display the Fraction

by having the lowest whole

numbers possible. The example on the right shows the 4th of the

1/8 inch marks in red. Since 4 is half way to 8 - it is the 1/2

inch mark. We could have said the 4/8 mark which is the same as saying 1/2 .

It is usually desired to display the Fraction

by having the lowest whole

numbers possible.

If the bottom

number (called the Denominator) can be divided by the number on top (called

the Numerator) and a whole number is the result

(no remainder) - the

Fraction would have the lowest number possible in the

Denominator.

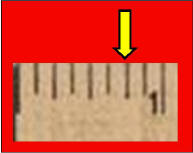

Looking

at the picture left and counting from the start or zero mark there are 6

spaces or 6/8 of an inch. Dividing 8 by 6 produces 1.333 which is NOT

a whole number (one with no decimal value left over.) However

both numbers can be made smaller. Any number or

Fraction can be

multiplied or divided by 1 without changing its value. This can be

accomplished by multiplying or dividing both the

Numerator and

Denominator

by the same number. Both the Numerator and

Denominator could be

multiplied by 2 (actually 2/2) that would give 6 * 2= 12 for a

Numerator and

8 * 2 or 16 for the

Denominator. The

Fraction would become 12/16; this

is the identical value as 6/8.

That would be accurate and a person could be told to say

"cut a

steel rod 12/16 of an inch long."

However the objective is to have the smallest numbers. Both

Numerator and

Denominator could be divided by 2. That would give 6/2 = 3 for a

Numerator and 8/2=4 for a

Denominator. The

Fraction now becomes 3/4.

It is the same value as 6/8 but with smaller numbers. Notice on the

ruler

some lines are longer than others. In this case the longest lines are quarters

of an inch rather than eighths. Three of these longest (quarter) lines could have

been counted and

the proper value found more quickly as the third quarter or the 3/4 mark! Looking

at the picture left and counting from the start or zero mark there are 6

spaces or 6/8 of an inch. Dividing 8 by 6 produces 1.333 which is NOT

a whole number (one with no decimal value left over.) However

both numbers can be made smaller. Any number or

Fraction can be

multiplied or divided by 1 without changing its value. This can be

accomplished by multiplying or dividing both the

Numerator and

Denominator

by the same number. Both the Numerator and

Denominator could be

multiplied by 2 (actually 2/2) that would give 6 * 2= 12 for a

Numerator and

8 * 2 or 16 for the

Denominator. The

Fraction would become 12/16; this

is the identical value as 6/8.

That would be accurate and a person could be told to say

"cut a

steel rod 12/16 of an inch long."

However the objective is to have the smallest numbers. Both

Numerator and

Denominator could be divided by 2. That would give 6/2 = 3 for a

Numerator and 8/2=4 for a

Denominator. The

Fraction now becomes 3/4.

It is the same value as 6/8 but with smaller numbers. Notice on the

ruler

some lines are longer than others. In this case the longest lines are quarters

of an inch rather than eighths. Three of these longest (quarter) lines could have

been counted and

the proper value found more quickly as the third quarter or the 3/4 mark!

|

|

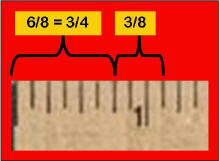

If

two Fraction dimensions are to be added (or subtracted) the numbers in the

Denominator (bottom numbers) must be the same.

Suppose two items are to be measured and a total length presented. If

one is 3/4 inches and the other 3/8 inches what is the total length?

Quarters and eights can not be added directly. It is best to convert

all measurements to the largest

Denominator, 8ths in this case. Therefore 3/4 becomes 6/8

(remember the

Numerator and

Denominator can always be multiplied by the same

number which is actually multiplying the

Fraction by 1.) The addition

is then with 6/8 + 3/8. The picture left shows the answer graphically. But

let’s get the answer using math. To add

Fractions, 6 of

the eight parts are being added to 3 of the eight parts. So only add the

Numerator

values (top

numbers.) Therefore 6 + 3 = 9 or 9 eights. Stated as a

Fraction, 9/8.

Whenever the

Numerator is bigger than the

Denominator the

Numerator can be

divided by the

Denominator to change to a whole number and possibly a

Fraction remainder. In this case, 8 goes into 9

once with one left over or 8/8 + 1/8 or 1 1/8 inches. This mark can be

seen on the ruler as one space after 1 inch. There would be nothing

wrong with saying the answer was 9/8 but suppose the result was 13 inches

and 3/8 inches. It could be stated as 13 * 8 or 104/8 + 3/8 or 104 + 3

=107/8. If it was necessary to measure using that dimension, 104

would be a lot of 1/8’s for someone to count! If

two Fraction dimensions are to be added (or subtracted) the numbers in the

Denominator (bottom numbers) must be the same.

Suppose two items are to be measured and a total length presented. If

one is 3/4 inches and the other 3/8 inches what is the total length?

Quarters and eights can not be added directly. It is best to convert

all measurements to the largest

Denominator, 8ths in this case. Therefore 3/4 becomes 6/8

(remember the

Numerator and

Denominator can always be multiplied by the same

number which is actually multiplying the

Fraction by 1.) The addition

is then with 6/8 + 3/8. The picture left shows the answer graphically. But

let’s get the answer using math. To add

Fractions, 6 of

the eight parts are being added to 3 of the eight parts. So only add the

Numerator

values (top

numbers.) Therefore 6 + 3 = 9 or 9 eights. Stated as a

Fraction, 9/8.

Whenever the

Numerator is bigger than the

Denominator the

Numerator can be

divided by the

Denominator to change to a whole number and possibly a

Fraction remainder. In this case, 8 goes into 9

once with one left over or 8/8 + 1/8 or 1 1/8 inches. This mark can be

seen on the ruler as one space after 1 inch. There would be nothing

wrong with saying the answer was 9/8 but suppose the result was 13 inches

and 3/8 inches. It could be stated as 13 * 8 or 104/8 + 3/8 or 104 + 3

=107/8. If it was necessary to measure using that dimension, 104

would be a lot of 1/8’s for someone to count! |

|

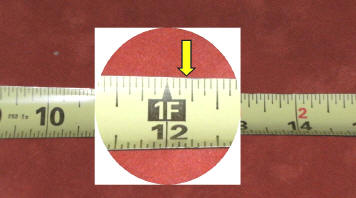

A

1 inch ruler mark is often split into 16

segments. These smaller

marks are still easy to read (compared to 32 marks which are used for some

steel rulers.) The picture left shows this segmentation with

the 1/8 inch marks and the 1/4 inch marks shown as longer red

lines. The

1/16 inch marks, shown in black, are the shortest. This makes it

easier to read quickly. A

1 inch ruler mark is often split into 16

segments. These smaller

marks are still easy to read (compared to 32 marks which are used for some

steel rulers.) The picture left shows this segmentation with

the 1/8 inch marks and the 1/4 inch marks shown as longer red

lines. The

1/16 inch marks, shown in black, are the shortest. This makes it

easier to read quickly.

A tape measure is the same as a ruler except

it is longer and flexible. There are also some interesting things to

note about most metal tapes.

The picture left is a

magnified section of a ruler.

This ruler is segmented into

1/16ths or 16 segments in an inch.

It is also labeled in feet as

well as inches. If a measurement is to be made to the yellow arrow it

is located at the 12 inch or 1 foot mark plus 3 spaces. therefore

there are 12 inches and 3/16 inches from the end of the ruler to the yellow

mark. The mark is said to be 12 and 3/16 inches or 1 foot 3/16

inches-both would be correct. This ruler is segmented into

1/16ths or 16 segments in an inch.

It is also labeled in feet as

well as inches. If a measurement is to be made to the yellow arrow it

is located at the 12 inch or 1 foot mark plus 3 spaces. therefore

there are 12 inches and 3/16 inches from the end of the ruler to the yellow

mark. The mark is said to be 12 and 3/16 inches or 1 foot 3/16

inches-both would be correct. |

|

There

are a few other things that should be understood about a tape measure: There

are a few other things that should be understood about a tape measure:

As seen in the picture right there is a metal

tab at the start end of the tape. It is usually attached with two rivets.

However it is loose. Do Not tighten these rivets with a hammer! The tab is loose for a reason.

I have talked with folks who think the ruler was made wrong and the rivet

was just not tight! That is wrong. It has a very useful purpose and

provides more accurate readings if used properly. It takes care of the

thickness of the metal tab when making outside and inside measurements.

We'll explain.

|

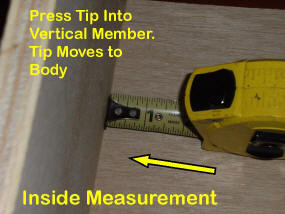

If you’re making

what is known as an “inside” measurement (picture left) - after the

tape is locked in position (with the black button on top) - the tape is pushed

with a slight force into the part to be measured. The looseness in the

tab is designed to take care of the thickness of the metal tab "IF" it is

pushed slightly to the vertical item being measured. The tab moves in

toward the ruler and provides an accurate measurement by properly

positioning the zero location. If you’re making

what is known as an “inside” measurement (picture left) - after the

tape is locked in position (with the black button on top) - the tape is pushed

with a slight force into the part to be measured. The looseness in the

tab is designed to take care of the thickness of the metal tab "IF" it is

pushed slightly to the vertical item being measured. The tab moves in

toward the ruler and provides an accurate measurement by properly

positioning the zero location. |

|

In

the photo right, the tape is being used to measure from the "outside" edge of

an item. In

the photo right, the tape is being used to measure from the "outside" edge of

an item.

The tape is pulled slightly away from the edge being measured and the tab

moves slightly away from the tape measure body. It moves the thickness of the

tab so that the zero point is now on the inside or from the photo the right

side of the tab. This places the zero location as necessary to have it

measure properly. This movement is accounting for the thickness of the

metal tab.

|

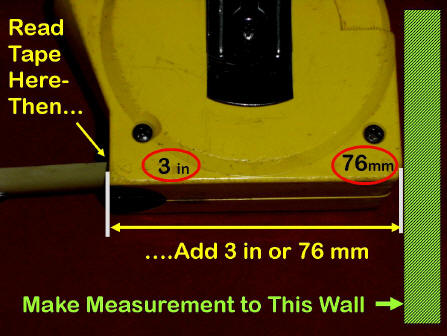

The tape

measure body often has a number printed on the base. This is a value

that can be used when making an inside measurement.

The measured value is read where the tape enters the tape body and the value

of its width added to that reading. For this ruler it is 3 inches.

The number 3 is added to the measured value to get the total

measurement. |

|

Metric:

Metric Units (now called

SI for international

Standard) are used by about every country accept the US. Many items

such as cars and trucks made and purchased in the US today use

SI dimensions, bolts etc! since parts

are made all over the world, many industries have standardized on metric or

SI units Metric Units (now called

SI for international

Standard) are used by about every country accept the US. Many items

such as cars and trucks made and purchased in the US today use

SI dimensions, bolts etc! since parts

are made all over the world, many industries have standardized on metric or

SI units

Metric

is actually a

simpler system and does not use

Fractions! All units are in 10ths. The

basic length measure is the meter (slightly longer that our yard.) The

preferred unit smaller than a meter is a 1000th of a meter called a millimeter

(the abbreviation is mm.) 100rdth of a meter is called a centimeter

(abbreviated as cm). A cm = 10 mm's. Everything is

expressed in 10ths or

multiples of 10. The ruler in the picture shows inches on top and

metric on the bottom. The top is segmented in 1/16th of an inch.

The metric is labeled centimeters with segments in millimeters. |

|

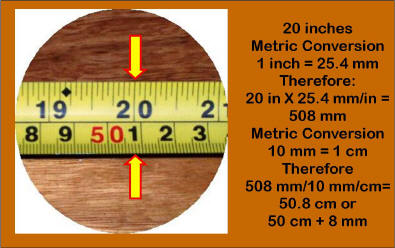

The picture

left shows a

conversion from 20 inches to metric. The ruler has

both US Units and metric units. As noted, 20 inches must be multiplied by

the conversion factor of 1 inch = 25.4 mm. Therefore 20 inches =

508 mm. Then 508 mm divided by 10 mm/cm = 50.8. Note all we have

to do to divide by 10 is move the decimal over 1 place. That yields

50.8. Or 50 cm and 0.8 cm. But a cm is 10 mm. So it could

be written as 50.8 cm or 50 cm + 8 mm. The picture

left shows a

conversion from 20 inches to metric. The ruler has

both US Units and metric units. As noted, 20 inches must be multiplied by

the conversion factor of 1 inch = 25.4 mm. Therefore 20 inches =

508 mm. Then 508 mm divided by 10 mm/cm = 50.8. Note all we have

to do to divide by 10 is move the decimal over 1 place. That yields

50.8. Or 50 cm and 0.8 cm. But a cm is 10 mm. So it could

be written as 50.8 cm or 50 cm + 8 mm.

Below are some Common Welding Metric

Conversions |

|

COMMON

METRIC WELDING CONVERSIONS |

|

TO CONVERT

FROM |

MULTIPLY BY |

TO OBTAIN

THIS METRIC TERM |

| inch (in) |

25.4 |

mm |

| foot (ft) |

305 |

mm |

| foot (ft) |

0.305 |

m |

| inches per

min travel (ipm) |

0.42 |

mm/sec |

| impact

(ft-lb) |

1.36 |

Joules |

| pound (lb) |

0.454 |

kg |

| ft3/hr (CFH) |

0.47 |

L/min |

| pressure

(psi) |

6.9 |

kPa |

| strength

(psi) |

0.0069 |

MPa |

| area (ft2) |

0.093 |

m2 |

| volume (in3) |

1640 |

mm3 |

| heat input

(J/in) |

39.4 |

J/m |

Welding Math and Physics PDF

|

|

There

is Much More Welding Math (and some Science) in Our 87 Page Self

Study Program,

"Welding Math and Science; Part # WMS

This program provides basic information to help

welding students and welding supervisors understand welding process

characteristics using basic math and science. Includes and Appendix with

Simplified Basic Math Functions and Metric Conversions.

CLICK for Purchase Page |

|