Compare the typical values in the above table with your usage.

Example; You purchased 46,000 lbs of 0.045

solid wire in the past 6 months and during the same period 610,000 CF of

Argon and CO2

combined:

Multiple the value from the far right column in the above table times the

wire purchase amount; 5.0 CF/ 1 pound X 46,000 lb

of wire purchased = 230,000 CF of gas you should have purchased.

But you purchased 610,000 CF of

gas. Therefore 610,000 – 230,000 = 380,000 CF was wasted or 380,000 Wasted

/ 610,000 Purchased = 62% Gas Wasted!

If you use several types of wire, treat each individually and add the

total gas requirements.

We have found this waste percentage to be typical

with some locations wasting significantly more!

Want a Guide that Summarizes

the Steps Needed to Define Your Gas Losses and Take the Action to Reduce Gas

Waste?

It is more detailed than this

simple example and provides a WORK SHEET where you can enter data.

Click on this

ICON F

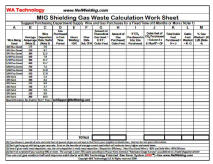

The

Guide Includes a way to develop a Work Sheet that makes calculating waste in

CF/year or as a percentage of what could theoretically be used easy and

accurate. Use the formulas provided to produce the spread sheet. Than place wire and gas usage data in the appropriate

columns and straight forward multiplication or division provides a total

waste calculation (Photo of sheet shown).

The

Guide Includes a way to develop a Work Sheet that makes calculating waste in

CF/year or as a percentage of what could theoretically be used easy and

accurate. Use the formulas provided to produce the spread sheet. Than place wire and gas usage data in the appropriate

columns and straight forward multiplication or division provides a total

waste calculation (Photo of sheet shown).