|

Argon Prices have more than doubled in 2014/15! PRAXAIR raised Argon Prices in July 2016, for a total of 35% in the year. AIR PRODUCTS raised Argon Prices 20% October 2016. Argon is in short supply, it's less than 1% of the air so very expensive new gas liquefaction plants cannot be justified until Oxygen demand increases.

Praxair Raises Argon and CO2 Prices Another 35% in 2016.

Helium shielding gas is even worse. Both Praxair and Air Products announce large price increases (~30%) for

Helium in January 2013. Click to see Airgas

CEO Discussion About Helium and Argon Shortages

PDF, "Why High Gas Cost?"

& way to fix it!

|

Shielding Gas Cost is Much Higher Than Often

Estimated. Shielding Gas Cost is Much Higher Than Often

Estimated.

What Percentage of Welding Cost is

Shielding Gas? |

| Unfortunately most published welding cost calculations are based on an incorrect

assumption that shielding gas usage is the flow rate set on a

flowmeter times the welding time! After understanding the data in this website and looking at

your "real" volume use and costs, you'll realize this is an erroneous assumption! |

|

First, evaluating what is typically published:

General Assumptions:

|

- a) 0.035 diameter solid wire operating at 190 amps. That

deposits 5.5 lbs/hr when the arc is on. Assume wire cost is $0.85/pound

- b) 30 CFH Shielding Gas flow. Assume cost of $0.10/cubic foot

for an argon based gas

(= $10.00/100 cubic feet)

- c) Direct Labor cost = $18.00/ hour

- d) Labor Overhead = 30% of Labor cost

|

|

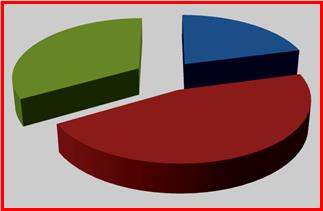

NO Gas Waste Case: With

the above assumptions and no consideration for shielding gas

waste, the resulting weld cost pie chart is shown on the

left. This is what is typically published as the method of calculating

shielding gas costs. Shielding gas is shown as only 5 % of total cost and less than

wire costs which are 7%. This is based on an erroneous

assumption of no gas waste. |

|

High Waste Case: To evaluate a high waste case, assume gas waste

is the high end defined in the literature, i.e. gas usage is, 30 CF/ lb of wire

(See References 1 & 2) with a high duty

cycle. Shielding gas would now be 32% of welding costs!

Probably higher than actual unless your welders are also setting much to

high a flow rate |

|

BOTTOM LINE:

Consider your real

gas usage when

estimating the cost of shielding gas and not a calculation based on an unrealistic

assumption!

Our Patented Gas Saver System

(GSS) Saves Typical MIG User 40 to

50% of Total Gas Used! Thousands are in Use.

See

Patented

Gas Saver System (GSS)

Solution

See Video: Demo and Solve Gas Waste

See

GSS Customer Testimonials: PDF Download

See Video: Science of MIG Shielding Gas Flow Control

|

|

Cost Calculations are Covered

in

"Lean Welding Manufacturing-Shielding

Gas"

Learning Program

"Optimizing Shielding Gas

Use and Eliminating Waste" includes details of this information in a

Do-It-Yourself 7 Module Program

It quantifies waste due to surge flow, leaks, ways to monitor

leaks and the gas flow settings where air is pulled into the shielding stream.

Unfortunately many are using far too much gas flow, wrongly employing the

philosophy, "If Some is Good More Must be Better" when it comes to

setting shielding gas flow rate!

|