| Flow Rate

Changes With Pipeline Pressure |

|

Both

Flowmeters and

Flow Control Orifices alter flow

rate as pipeline pressure varies. Depending on the pipe size and

configuration, pipeline pressure changes occur as additional welding

machines are placed in use. Just how much does the flow change?

We conducted the following Laboratory tests to demonstrate these flow

changes. |

|

Want a Detailed Report

on the Following Test Data?

It includes a

table with correction factors to calculate actual from measured flow

when pipeline pressure varies.

CLICK HERE to Download FREE PDF Copy: |

|

Alert

!! Alert

!!

Argon

Prices Doubled in the Past Several Years. Two European Companies ow have 77% of the US Production Capacity! It Will Remain in Short Supply -Expect Even Higher Prices!

(See Details in Video)

Time to "Lock" Your Flowmeters with Our Flow Rate Limiter.

The Flow

Rate Limiter (FRL) is our latest gas saving patent. It's

simple and does not alter the flowmeter. Just set the maximum flow

desired and slip the billet aluminum FRL over the control knob

so its stainless pin prevents further increases. Then tighten the

setscrew with included Allen wrench. An optional brass lock prevents

setscrew access.

CLICK Here or Picture for Details

Our FRL is a Perfect Compliment to Our

Gas Saver System (GSS.)

With Both You'll Save Over 50 to 60% of Shielding Gas Use! |

|

TEST PROCEDURE:

A pipeline flowmeter was connected to a

test pipeline that had its inlet pressure controlled by an inert gas regulator

connected to an Argon/CO2 shielding gas cylinder. The cylinder regulator allowed pipeline pressure to be varied from 20 to 75

psi. To assure pressure reading accuracy a calibrated 2 inch diameter gauge

was installed in the regulator outlet gauge port.

cylinder. The cylinder regulator allowed pipeline pressure to be varied from 20 to 75

psi. To assure pressure reading accuracy a calibrated 2 inch diameter gauge

was installed in the regulator outlet gauge port.

The flowmeter selected

for the test was a commonly used Victor* FM372 (photo right.) As noted in the Victor

literature, all their flowmeters are calibrated at 25 psi (accept one for CO2

which is calibrated at 80 psi to avoid ice particles in the needle

valve.) They note that the pressure is used to provide what we refer to

as "Automatic Flow Compensation"

that requires a pressure of 25 psi or greater. Therefore

the flow reading scale will only be accurate at a pipeline pressure of

25 psi. Increased pressure will produce a higher flow than what is

read on the flow tube. These Laboratory tests demonstrate just how much more

flow variation occurs with pipeline pressure changes with a fixed flow control knob setting. |

|

MEASURING ACTUAL FLOW:

To

measure the actual flow we used a portable flowmeter, our part number

WAT- PFM. This uses the same flow

measuring principle defined by

Bernoulli in the 1700's. It is accurate and very repeatable. It was used in a way

recommended in our Lean Welding Manufacturing Self Study

Training Programs which is to measure flow with

the wire feeder gas hose fitting placed in the gauge (photo left.)

Therefore there is no possibility of leaks between the Victor FM372 and the

portable flowmeter. Instructions shipped with the WAT-PFM define how this

measurement approach in combination

with measuring at the MIG torch nozzle quantifies leaks in wire feeder plumbing, torch to feeder connections,

backflow through wire outlet guide etc and what differences are excessive. To

measure the actual flow we used a portable flowmeter, our part number

WAT- PFM. This uses the same flow

measuring principle defined by

Bernoulli in the 1700's. It is accurate and very repeatable. It was used in a way

recommended in our Lean Welding Manufacturing Self Study

Training Programs which is to measure flow with

the wire feeder gas hose fitting placed in the gauge (photo left.)

Therefore there is no possibility of leaks between the Victor FM372 and the

portable flowmeter. Instructions shipped with the WAT-PFM define how this

measurement approach in combination

with measuring at the MIG torch nozzle quantifies leaks in wire feeder plumbing, torch to feeder connections,

backflow through wire outlet guide etc and what differences are excessive.

As we do with each

batch of flowmeters, we checked the one used for these tests with calibrated

regulator/flowmeters placed on the cylinder. The WAT-PFM was accurate and correlated

with the regulator/flowmeters within our measurement precision from 20 to

40 CFH.

The following are the

results of the tests: |

| Pipeline

Pressure |

Reading on FM372 Flowmeter Flow Tube |

Published Correction Factor |

Flow Using

Correction Factor |

Actual Flow

Measured on Portable Flowmeter |

| 25 psi |

20 CFH |

1.00 |

20 CFH |

20 CFH |

| 30 psi |

23 CFH |

1.05 |

24 CFH |

23 CFH |

| 35 psi |

24 CFH |

1.12 |

27 CFH |

28 CFH |

| 40 psi |

26 CFH |

1.18 |

31 CFH |

32 CFH |

| 45 psi |

27 CFH |

1.23 |

33 CFH |

34 CFH |

| 50 psi |

31 CFH |

1.28 |

40 CFH |

40 CFH |

|

|

INTERPRETING TEST RESULTS:

Looking at the first

row of data. The pipeline pressure was set at 25 psi which is the

calibration pressure for the FM372 flowmeter. The 2nd column shows the

reading on the FM372 flowmeter which was 20 CFH since the flow knob was

adjusted to that flow setting. The next column is the published factor used to

correct for pressure differences between the actual pipeline pressure and

the calibration pressure. Since 25 psi is the calibration pressure

the factor is one. Therefore applying the factor shows 20 CFH in the

third column.

The last column is the flow measured on the WAT-PFM which, as expected, is also

20 CFH. This also validates the calibration of the

FM372 and the WAT-PFM flowmeter are the same. |

|

Examining the third row

of data; the pipeline pressure was raised to 35 psi with NO CHANGE IN

THE INITIAL

FLOW KNOB SETTING. The FM372 flow now read 24 CFH. The published correction

factor for the increase in gas density is 1.12. Applying this

correction factor shows an actual flow for an observed 24 CFH reading to be 28 CFH.

Therefore although the gauge on the Victor FM372 was reading 24 CFH the

actual flow was theoretically 28 CFH. The extra flow is because the

density difference in the gas from the 25 psi calibration pressure and the

35 psi in the pipeline. The actual

flow as measured on the WAT-PFM was 27 CFH which is within our

measurement precision of the theoretical 28 CFH. |

|

Looking at the last

row of data. Pipeline pressure was raised to 50 psi and the FM372

flowmeter now read 31 CFH. The correction factor for 50 psi is 1.28

yielding a theoretical flow of 40 CFH (31 X 1.28) for a 31 CFH

FM372 flowmeter reading. The calculated flow is the same as the actual flow

measured on the WAT-PFM that was also 40 CFH. That is 29%

more actual flow then measured on the FM372 flowmeter [(40-31)/31=29%. ]

Therefore if this flowmeter (or any calibrated at 25 psi, as are many) is

operated at a pipeline pressure of 50 psi and gas flow set at a reading of 31 CFH

using the flowmeter scale, the actual flow would be 40 CFH! That is

29% more flow

than read on the pipeline flowmeter scale. Not only is this wasting

gas but it could exceed

the

allowable range defined in a Welding Procedure Specification (WPS.)

|

|

TEST OF FLOW CONTROL ORIFICE:

Similar tests were

conducted using variations in pipeline pressures with our Standard Flow Control

Orifice, OGSS-45. We

compared the theoretical flow rate based on orifice size and pressure with

that read on the WAT-PFM. Here are the results: |

|

Pipeline

Pressure |

Theoretical Flow

Based on Orifice Size and Pipeline Pressure |

Actual Flow

Measured on Portable Flowmeter WAT-PFM |

|

25 psi |

25 CFH |

25 CFH |

|

30 psi |

30 CFH |

30 CFH |

|

35 psi |

33 CFH |

33 CFH |

|

40 psi |

35CFH |

36

CFH |

|

45 psi |

40 CFH |

41 CFH |

| 50

psi |

45CFH |

44 CFH |

|

|

As seen from the data, the flow measured on the WAT-PFM through a OGSS-45

Flow Control Orifice is very predictable and within the measuring precision of the theoretical flow based

on orifice size, pressure and flow calculations. |

|

BOTTOM LINE:

If

employing pipeline supplied shielding gas and using an Orifice to Control If

employing pipeline supplied shielding gas and using an Orifice to Control

Flow,

a Portable Flowmeter is the way to verify the actual flow. The flow

through the Orifice changed about 8 CFH with a 10 psi pipeline pressure

change. This is as predicted by

"critical flow" flow equations. Flow,

a Portable Flowmeter is the way to verify the actual flow. The flow

through the Orifice changed about 8 CFH with a 10 psi pipeline pressure

change. This is as predicted by

"critical flow" flow equations.

When using a Flowmeter to control

shielding gas flow from a pipeline, when pressure

changed 10 psi the actual flow changed a similar 8 CFH.

Therefore pipeline pressure changes produced essentially the same flow variations in

both Flowmeters and with Orifices used to set flow.

Note: When using

Regulator/Flowmeters on cylinder shielding gas supply, these flow reading

variations DO NOT exist as the regulator maintains the proper calibration

pressure of 25, 50 or 80 psi.

Why Not Use a Cylinder Regulator/Flowmeter

on a Pipeline Supply

to maintain a fixed pressure?

Answer: Because it will not

maintain a constant pressure with only a 40 to 100 psi input! These

devices are designed to operate over a wide range of inlet pressure, from

2500 psi though about 200 psi and the accuracy of control even

decreases at the lower inlet pressures! Valve size, diaphragm size and

spring pressure are all designed to this wide pressure range, especially the

very high pressure. If you want to use a regulator, you must select

the proper type. See below, and email: |

|

Check

Pipeline Pressure with our WAT PTD Check

Pipeline Pressure with our WAT PTD

The WAT PTD

consists of a 0 to 100 psi industrial pressure gauge with a CGA 032 "B"

female fitting on one side and male CGA 032 "B" fitting on the other.

Just unscrew the gas delivery hose from the gas supply or feeder end and

insert the WAT PTD. The pipeline pressure can be tested since the gas

pressure in the gas delivery hose rapidly increases to the pipeline pressure when welding stops. The

device can be used to quickly test pipeline pressure at the wire feeder gas

inlet in

several areas of the shop.

Full details are

provided with the Instructions that accompany the

product.

Download this PDF for more details:

WAT PTD Purchase Details:

Click to See Video Overview

Click to See Full Video Details |

|

Does Your Pipeline Pressure Vary a Lot?

There are

several things you can and should do:

You can add a

regulator designed to control pressure from pipeline pressures to a stable

50 psi or 25 psi before flowmeters or fixed orifices. We have seen cylinder regulator/flowmeters used in

attempt to provide this function. This DOES NOT work!

Being designed to control from 2500 psi they are not accurate with low inlet

pressures!

The proper

regulator to use must be designed with proper size valve seats, correct diaphragm

and spring. There are regulators

designed

for that purpose usually called station regulators. Some of these are

expensive high flow models, however there are other lower cost models which

can be used for one or two flowmeters. The one shown on the left is designed to accept up

to 200 psi inlet pressure and will hold a constant output at the preset

pressure. .

A designed

for that purpose usually called station regulators. Some of these are

expensive high flow models, however there are other lower cost models which

can be used for one or two flowmeters. The one shown on the left is designed to accept up

to 200 psi inlet pressure and will hold a constant output at the preset

pressure. .

A flowmeter (or a fixed orifice) can be easily added to the output fitting.

flowmeter (or a fixed orifice) can be easily added to the output fitting.

This regulator has

the capacity to handle several flowmeters. On the right is an

inexpensive adapter that makes it easy to add two flowmeters. This

system works great with our

GSS.

The

GSS.

will quickly save enough shielding gas to pay for the regulator within a few

weeks!

Email

for details and part number information:

|

|

Using Small ID Shielding Gas Pipelines

and High Pressure to Offset Pressure Drops?

We Have Two

Patents that Accomplish Pressure Control and Gas Savings While Keeping Pressure Above 25 psi to Maintain

"Automatic Flow Compensation"

These systems work with any

length gas delivery hose. One simple system is available that works

with any length existing gas delivery hose, even one 200 feet or longer!

Email for

details.

Email with the following information:

1) Location: City

and State

2) Pipeline

pressure range

3) Type of

existing flow control (flowmeter, orifice)

4) Range of gas delivery hose lengths (pipeline drops to feeders) |

| |

|

Want a detailed report

on the above test data? It

includes a table with correction factors to calculate actual from

measured flow when pipeline pressure varies over a range from 20 to 70 psi.

CLICK HERE to

Download FREE PDF Copy: |

|

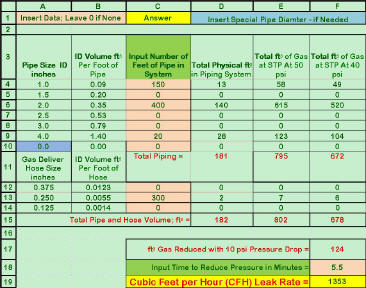

Measure Pipeline

Leak Rate:

Having

problems with leaking pipeline and hoses? There is a simple way to

measure the leak rate. Use a leak down Pressure Test. The

equations needed to develop a

Spreadsheet are provided with our

"Lean Welding

Manufacturing-Shielding Gas" (part # LWM-SG) Program that makes it easy to calculate.

It is available for purchase on this web page. Having

problems with leaking pipeline and hoses? There is a simple way to

measure the leak rate. Use a leak down Pressure Test. The

equations needed to develop a

Spreadsheet are provided with our

"Lean Welding

Manufacturing-Shielding Gas" (part # LWM-SG) Program that makes it easy to calculate.

It is available for purchase on this web page. |

| |

Purchase Gas Saving Products |

Purchase Training

Aids |

Purchase

Flow Rate Limiter |

Purchase Wire Feeding

Aids |

Cable Covers & PLASMIT Torch

Protectors |

Purchase Orifice Flow Control

System |

| *Victor is a registered trademark of

Victor Technologies Corporation |