|

Only

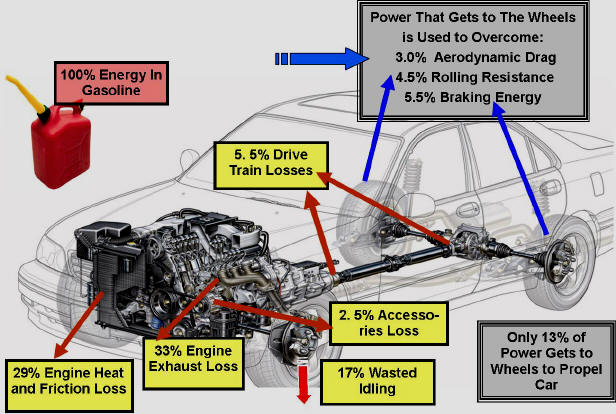

About 13% of the Energy in Gasoline Gets to the Wheels to Power the

Car!

Where Does It All Go? |

| The Following Graphic is the

Approximate Distribution of the Energy in Gasoline as Used by a Car in

Typical Operation.

Once it gets to the wheels, how its distributed is up to the way the

car is being used. Typical use is shown. |

|

| This picture presents an average usage of

the energy in gasoline.

Aerodynamic drag can be a much higher percentage if you travel fast.

It becomes a much bigger factor at speeds above 50 MPH. Since drag is

proportional to the speed squared, 70 mph will create twice the drag as 50

mph! (702 / 502 = 1.96) |

|

What Can You Do To Improve

Efficiency? Some Thoughts:

|

|

|

|

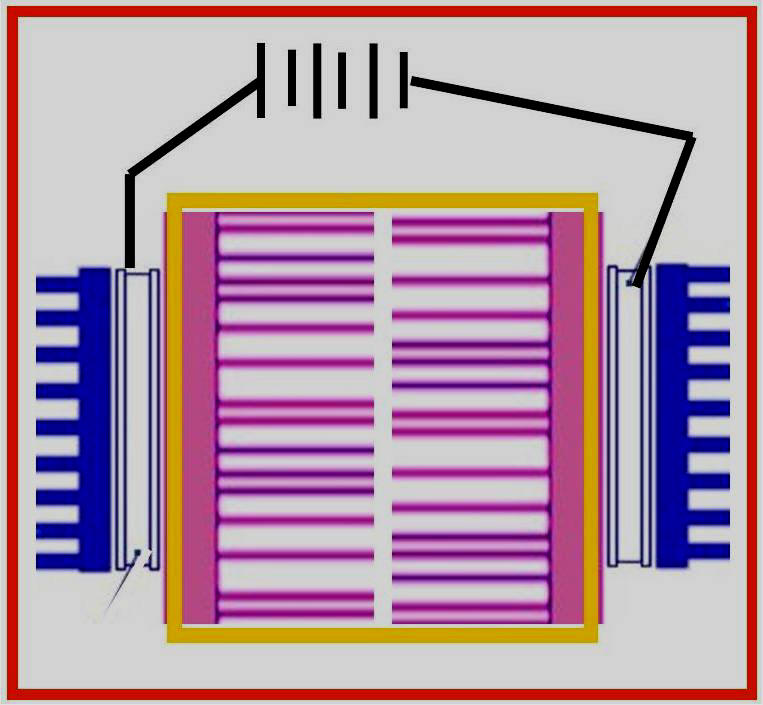

Two Concepts shown below for Using Peltier

Effect Modules. At <~$50 for 100 watt modules these could be placed

along a section of exhaust pipe to recover some of the 33% of energy in

gasoline going to waste! |

Two Peltier Modules placed in a square

section of exhaust pipe with heat extracting fins could provide power to

charge batteries. More could easily be added. |

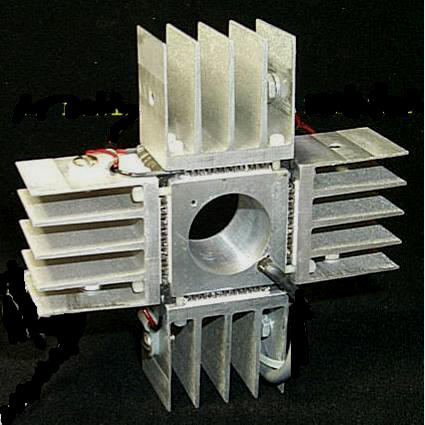

Multiples of "Four Peltier Modules"

placed around an aluminum exhaust sections could be placed in an

air-conditioning duct! |

|

Hot Rod Approach to Braking Energy Recovery

Braking creates 5.5% wasted energy

or about 42% of the energy that gets to the rear wheels!

Hybrids collect some of that energy. Braking creates 5.5% wasted energy

or about 42% of the energy that gets to the rear wheels!

Hybrids collect some of that energy.

I recall a photo many years ago on the cover of

one of the Rodding Magazines that showed a Tee Bucket with the

alternator mounted to the driveshaft at the rear end. This avoided

cluttering the engine compartment with accessories. The photo on the

left is similar to what was shown on that cover. The alternator is a

bit hard to see but the red arrow is pointing the chrome alternator pulley

and the belt can be seen going to another pulley mounted on the universal attached

to the pinion shaft.

How about

mounting a 250 amp Chevy Truck

alternator

(photo left, $299 new) and connecting it to batteries through a HD power

relay only when the brake peddle is pressed. (Note: A welding power

supply contactor can handle that level of DC current and is reasonably

priced.) That's 3000 Peak

Watts or about 4 HP! That will slow down the car by charging a

few deep cycle batteries connected in parallel. Optima Yellow Tops

are designed for deep discharge and can handle high current charging.

The batteries could run

electric air-conditioning, radio, lights etc! Then when stopped,

the engine can be turned off and only started when ready to take off again. alternator

(photo left, $299 new) and connecting it to batteries through a HD power

relay only when the brake peddle is pressed. (Note: A welding power

supply contactor can handle that level of DC current and is reasonably

priced.) That's 3000 Peak

Watts or about 4 HP! That will slow down the car by charging a

few deep cycle batteries connected in parallel. Optima Yellow Tops

are designed for deep discharge and can handle high current charging.

The batteries could run

electric air-conditioning, radio, lights etc! Then when stopped,

the engine can be turned off and only started when ready to take off again.

(Note: Test drove a 2011 V8 Porsche

Cayenne that shut the engine off when stopped! Could not tell that it

restarted it was so smooth! It just uses a lead acid battery and heavy

duty starter. Assume they ran the air-conditioning taking advantage of

the cooled evaporator coils for a short time. Specs said this feature

will operate on all but very hot days and will start the engine if battery

power is low.) |

|

Formula 1 Uses KERS (Kinetic Energy

Recover Systems for 2009 (It was not used in 2010 but Ferrari announced it

will use it again in 2011. Ferrari wanted to use a system with more

power but that was turned down.)

The folks who ran KERS for 2009! Most teams employing KERS are

using generators charging batteries like the suggestion made above to

recover braking energy. F1 regulations are designed to allow the KERS

to deliver about 80 HP for 6 seconds each lap.

The systems weight about

75 pounds.

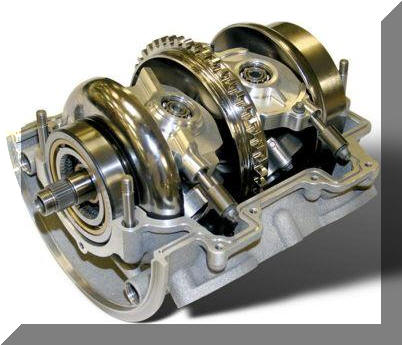

However Williams is using a

device that always intrigued me-a flywheel!

One system

uses a

flywheel spinning at up to 40,000 rpm to recapture kinetic energy.

Under braking, the rear wheels turn a motor/generator that spins up the

flywheel. The driver can press a "boost button" on the steering wheel the

flywheel releases its energy to drive the motor and provide an extra power

boost.

Companies

like Flybrids (www.flybridsystems.com) and Xtrac (www.xtrac.com) are working

with the F1 folks as well as developing commercial systems. Some

operate as "all mechanical system" using a Constant Velocity Transmission

(CVT) to spin-up the flywheel and then delivery mechanical energy back to the

wheels. Companies

like Flybrids (www.flybridsystems.com) and Xtrac (www.xtrac.com) are working

with the F1 folks as well as developing commercial systems. Some

operate as "all mechanical system" using a Constant Velocity Transmission

(CVT) to spin-up the flywheel and then delivery mechanical energy back to the

wheels.

Some systems use a flywheel

connected to the vehicle transmission to store energy under braking and

recovers it when the vehicle reaccelerates. A CVT controls speeds

proportionate to the torque transmitted through the device. This

system reportedly has half the mass of hybrid battery systems, and a more

rapid energy transfer. The flywheel is made of steel with a

filament-wound carbon fiber rim and rotates in an evacuated chamber at

speeds between 32,000 and 64,500 rpm. In addition to limit he vacuum acts as

a natural noise barrier. Another system uses high pressure hydraulics

stored in an "accumulator"

to store and delivery energy.

Flywheel Theory

The Energy Stored in a

flywheel = 1/2 * Moment of Inertia (the

shape and weight of the flywheel) *

RPM2

If you can get all of the

flywheel weight out toward the rim you have the maximum Inertia for a given

weight. If it could all be at the rim the equation becomes:

Ke=1/2(Mass

*

radius2) rpm2

Therefore the most energy storage per given weight occurs with

a large radius and high rpm. The radius is limited by the forces

acting to pull the rotor apart so composites not steel are used. The

rpm of 40,000 mentioned for the Formula 1 systems shows the drive for high

rpm. Friction becomes a major issue as does air drag. So most

efficient systems operate in a vacuum and use magnetic bearings.

Flywheels have the potential to store 10 times the energy per pound than a

battery and don't have a limited life. The key is transferring the

energy mechanically efficiently. The Williams F1

team is apparently

looking at a system that can operate up to 100,000 rpm! Hmm- be sure

your up at the top of the stands if your going to watch when that car is

running!

The Formula 1 effort is to be

applauded. This free enterprise driven system can do far more with

much less money than a government sponsored research effort!

In addition, it saves a lot of trees required with Government Sponsored

Contracts which require tons of pages in mostly useless reports! |

|

Porsche Did It !

Porsche announced their

Hybrid Racer ! These are the details from their press release:

"The company's hybrid drive technology - developed for racing - uses an

electric front axle drive system with a pair of 60kW ( 80 HP )

electric motors adding a boost to the car's already stroppy (had to look

that up- "Noisily Aggressive") 353kW (474 HP) flat six engine.

Rather than weighty batteries - like those used in hybrid road cars like

the Toyota Prius - it uses an electrical flywheel generator.

The 40,000 rpm generator is charged whenever the brakes are applied, and

stores power as kinetic energy. This 120kW (161HP) of power can be

released for approximately six to eight seconds after each charge,

converting previously wasted energy into a valuable boost out of corners or

when passing. Porsche reckons the system will also save fuel, cutting down on fuel

weight and pit stops."

Let's See-161 extra HP for 6 seconds is all I need in my Vette!!

And when I take off it will be using previously wasted braking energy instead

of gasoline! This is better than Nitrous! |

|

Porsche Will Produce Fast Green Car

The

918 Spyder

plug-in hybrid

pairs a 3.6-liter 500-horsepower

V8 with three electric motors

(one on

each front wheel and one in the transmission. )

The electric

motors produce a peak 215 HP and are

powered by air-cooled lithium-ion

batteries.

That is a total of 715 hp and it incorporates

F1 type KERS overboost! The

918 Spyder

plug-in hybrid

pairs a 3.6-liter 500-horsepower

V8 with three electric motors

(one on

each front wheel and one in the transmission. )

The electric

motors produce a peak 215 HP and are

powered by air-cooled lithium-ion

batteries.

That is a total of 715 hp and it incorporates

F1 type KERS overboost!

The 918

Spyder is constructed from a carbon-fiber monocoque chassis and

engine cradle. Curb weight is 3,285 pounds.

Top speed is198 mph with a zero-to-60 time of 3.2

seconds. It can function in a thrift mode with only the electric motors

propelling the car. It has an EPA type

test

average 78 mpg! However like the Chevy Volt, it

is difficult to compare with all gasoline cars. Is the

Tesla infinite?!

The

price or volume have not been established but is expected to be very high

priced and produced in low numbers. Perfect for a very rich “early adopter! |

| I am confident there are

other even better ideas to consider like improving the engine efficiency.

Expect inventors, new engineers and entrepreneurs will tackle these opportunities! |

|

Want Some Ideas on How to Save 20% or More

Gasoline?

CLICK |

|

Use Ethanol to Reduce

Fossil Fuels? CLICK |

| . |

|

Have a Welder? You Can Save a Higher

Percentage of MIG Shielding Gas Than You Can Gasoline with Our

Patented Gas Saver System (GSS)!!

You'll Also Improve Weld Starts and

Have a Shielding Gas Cylinder Last at Least Twice as Long!

Note: Our Patented

GSS

is Not Available in "Stores"

A home shop fabricator

in Georgia with a MillerTM 175 amp welder

purchased a 50 foot Gas Saver System ( GSSTM

) so he could use a larger cylinder

and mount it on the wall of his shop. He wrote:

"The system works great.

Thanks for the professional service and

a great product."

Click To See His Home Shop

A Professional

Street Rod Builder Had This to Say:

With their standard MIG welder gas delivery hose the

peak shielding flow at weld start was measured at 150 CFH. That caused air

to be sucked into the gas stream causing poor weld starts. With the GSS replacing their existing

hose, the peak flow surge at the weld start was about 50 CFH. Total gas use

was cut in half.

Kyle Bond, President, quickly saw the improvement

achieved in weld start quality as a significant advantage! Kyle, an

excellent automotive painter, was well aware of the effects of gas surge

caused by pressure buildup in the delivery hose when stopped. He has to

deal with the visible effects in the air hose lines on the spray gun in his

paint booth! The paint surge is visible and creates defects unless the gun

is triggered off the part being painted! We can’t do that with our MIG gun!

|

|

MIG Gas Delivery and the Small Block Chevy

Evolved in a Similar Way and Time!

Both had Advances and

Setbacks Before

They Were Optimized!

Click

for a PDF Report on the Similarities |

|

Want Some Ideas on How to Save 20% or More

Gasoline?

CLICK |

|

Use Ethanol to Reduce

Fossil Fuels CLICK |

|

Purchase Products |

Purchase Gas Saving Products |

Purchase Training Aids |

Purchase

Flow Rate Limiter |

Purchase Wire Feeding Aids |