A Message about our patented shielding Gas Saver System (GSSTM) from the President of WA Technology, Jerry Uttrachi. (Mr. Uttrachi, was Director at Large, VP for 3 years and elected as the 2007 President of the 75,000 Member American Welding Society. He served on the Societies Education Foundation Board for 15 and was Board Chairman for 6 years, (all volunteer positions.) In 2012 his book, entitled, "Advanced Automotive Welding," (available on this website at a big discount, CLICK) and a book released in 2015 "Weld Like A Pro," were published by CarTech.

|

|

MIG Welders Waste 60 to 80% of the Shielding Gas They Use ! |

|

Overview of Gas Saver System

Easy Installation: Simply remove your existing gas delivery hose from gas supply to feeder or welder. Just replace it with the GSS. The end fittings employ the same threaded connections used on most commercial wire feeders/welders and gas supply regulators or flowmeters. |

| The Problem - Excess Shielding Gas stored in the delivery hose when welding is stopped is wasted every time the MIG torch switch is energized, even when just inching the wire. The excess can exceed the amount of gas used while welding! Inferior weld starts result from the high gas surge flow pulling air into the shielding gas stream. |

The Gas Saver System

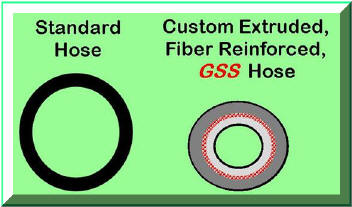

solves this surge flow problem. The system employs a custom made gas

delivery hose with 75% less volume than conventional hoses. A surge

flow restrictor further reduces waste to over 80% and improves starts. The surge

restrictor does not limit normal gas flow settings. solves this surge flow problem. The system employs a custom made gas

delivery hose with 75% less volume than conventional hoses. A surge

flow restrictor further reduces waste to over 80% and improves starts. The surge

restrictor does not limit normal gas flow settings.How much excess gas can be stored in a 1/4 inch delivery hose? Up to 6 times the physical hose volume! To see why CLICK. |

|

Superior Starts are achieved by limiting surge flow velocity to an acceptable level by the use of an integrated surge flow restrictor. The patented design maintains system pressure to retain automatic flow compensation built into standard gas delivery systems since the invention of MIG and TIG! High pressure also helps to quickly provide a controlled amount of extra gas at the weld start to purge air from the torch nozzle and weld start zone. See:

|

|

The GSS Has No Moving Parts to wear or maintain or knobs to adjust. It is inexpensive with Payback measured in weeks. |

The GSS is a

Patented Gas Delivery Hose incorporating a Surge Limiter That Can Save 50% of

MIG Shielding Gas Use and Improve Weld Start Quality.

The GSS is a

Patented Gas Delivery Hose incorporating a Surge Limiter That Can Save 50% of

MIG Shielding Gas Use and Improve Weld Start Quality.