|

Why is Extra Gas Needed

for MIG Weld

Starts?

We

are often asked

why certain devices such as restriction orifices mounted at the feeder to

control flow do not work or why welders complain about their use. The

following are some answers:

|

|

Question:

Why is some extra gas needed at the weld start?

Answer: Some devices designed to reduce

gas waste supply insufficient extra gas at the weld start to counteract the air entering the torch

nozzle, body and cable when welding is stopped or in the weld start area. Some of these devices

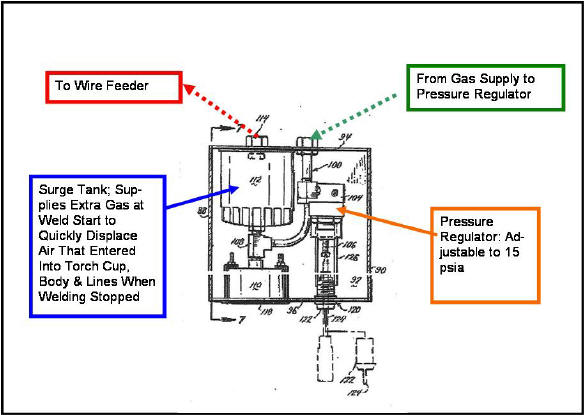

control flow at the wire feeder. Stauffer in a patent published in

1982 ( Patent Number 4,341,237) discusses this issue. He clearly

understood the problem and designed around it using a "surge storage tank"; he states in the patent teaching (see pic below.)

"... air leaks back into the torch and lines when

welding is stopped. The air must be quickly purged and replaced with inert

gas to produce high quality welds.

Also, it is

critical to displace the air at the weld zone of the work piece upon initiating

the weld.

"

|

The patented device by Stauffer employed a "surge storage tank" to store extra gas when welding stopped and delivered it back at each start. He define the need in his patent teaching. The patented device by Stauffer employed a "surge storage tank" to store extra gas when welding stopped and delivered it back at each start. He define the need in his patent teaching.

This device improved weld start quality, unfortunately is operated at lower than 25 psi and did not incorporate "automatic flow compensation." |

|

Question:

What are the devices that cause lack of sufficient

extra gas at the weld start?

Answer: Any device that

attempts to control flow at the wire feeder will not have sufficient "stored

gas" that can be quickly delivered to the welding torch cable, torch nozzle

or weld start area. This can be a:

Flowmeter,

Orifice that is controlling gas flow,

Needle valve or

Regulator/ flowgauge (low or

high pressure.) Note, low pressure regulator devices have added problems.

(See Q&A About Automatic Flow

Compensation)

|

|

Question: We're

using a flowmeter at the gas source (cylinder or pipeline.) Do we have

a lack of start gas problem?

Answer: No you probably have

much more than enough excess gas but the initial flow surge velocity is so

high your pulling moisture laden air into the weld start area and creating

similar problems. You can hear the gas surge when you pull the torch

nozzle - (CAUTION be sure the wire feeder pressure roll is disconnected

when you listen and do not touch an electrically energized part of the torch

to your body!!)

You Need Our Gas

Saver System (GSS),

Check It Out. |

|

Question:

What happens if we don't quickly have sufficient extra gas at the weld

start?

Answer: You're essentially

starting the weld in moisture laden air until the MIG gun cable, gun nozzle

and weld start area get fully displaced by the shielding gas. About 5%

air is sufficient to create Nitrogen porosity

(See

Reference.) Welders often see this problem and try to counter

with higher steady state flow rate settings. That is only partially successful

and the higher steady state flow rate wastes gas! They may also increase the

rate so high they create turbulence in the shielding gas stream This

only pulls in moisture laden air and is counterproductive. |

|

Question: Is that

why when we have used orifices mounted at the wire feeder to control

shielding gas flow welders complained and sometimes drilled out the orifice?

Answer:

We have found that to be the

case. Welders may drill out the orifice believing they need higher gas

flow (which they may - but just at the start.) However the smallest

drill commonly available in a drill bit set is 1/16 inches. Sounds

like a small hole but on a 50 psi shielding gas pipeline that will provide

in excess of 150 CFH flow! This not only wastes gas but also pulls in

moisture laden air creating internal if not visible weld porosity and excess starting spatter similar to the lack of extra gas..

Welders have no doubt experienced what the lack of start gas can cause. They may have started to weld and forgot to open the gas cylinder, a common occurrence. Starting to weld without sufficient extra start gas to purge the gun nozzle and weld start zone is like welding for a few seconds with the gas cylinder shut off! When managing a filler metals and welding process R&D Lab I would occasionally be asked to look at a new flux cored wire of even sold wire. I would put on a ab coat, gloves and helmet and prepare to weld. One of our highly skilled technicians would purposely have the gas cylinder turned off as a "joke" when the "boss came to weld!" It took a few seconds for me to see that excess spatter through the darkened helmet!

|

|

Question:

Are there specific

production instances where a switch to some extra gas at the start helped

weld performance?

Answer: Yes, the following

two examples

validate the need for some extra gas at the weld

start:

First Case:

A

bar joist manufacturer was using flow control orifices mounted at the wire

feeders. Argon/CO2 shielding

gas is supplied in a pipeline

through about 15 feet of gas delivery hose. The flow control orifice

established the flow at 45 CFH. However the welders wanted higher flow

rates with some even drilling out the orifice! The welding engineer wanted to avoid wasting

shielding gas. With this flow setting arrangement where control is mounted at

the feeder next to the gas solenoid there is insufficient extra gas provided at the weld start.

This lack of extra gas prevents to purging the weld start area

of moisture laden air. gas is supplied in a pipeline

through about 15 feet of gas delivery hose. The flow control orifice

established the flow at 45 CFH. However the welders wanted higher flow

rates with some even drilling out the orifice! The welding engineer wanted to avoid wasting

shielding gas. With this flow setting arrangement where control is mounted at

the feeder next to the gas solenoid there is insufficient extra gas provided at the weld start.

This lack of extra gas prevents to purging the weld start area

of moisture laden air.

A test was made to check weld performance and

potential shielding gas

savings using two cylinders of shielding gas on two adjacent welders instead

of their pipeline gas supply. One was set with their

standard flow control orifice system and a regulator providing a pressure

that matched their pipeline, 50 psi. The other with a

regulator/flowmeter (also of a 50 psi design) using a 15 foot

GSS without their flow control

orifice. Both steady state flows were set at 45 CFH. Since welders stand side

by side, it was easy to observe the weld start quality! Instantly the

welder using the

GSS noticed improved

starting. After about an hour with observably better results the

welding engineer suggested we lower the shielding

gas flow on the welder with the

GSS to 35 CFH! The same improved weld start quality

was observed and the welder was "happy." In

fact even though we lowered the steady-state flow to 35 CFH there was still

about the same controlled amount of extra gas available at the start (that

stored in the GSS

hose when welding stopped.) The higher start gas flow rate established by the

surge flow orifice in the

GSS

maintained the higher flow at the start.

This higher start flow rate quickly flooded and purged the weld start area of

moisture laden air.

It was this air that was casing

excess spatter and lack of shielding on all their other welders! After about 4 hours of observation it was obvious the spatter

at the weld start was less with the GSS.

We also measured a reduced use of shielding gas of 25%.

After several months of testing to check this one system during windy days etc,

this shop now has

GSS's installed on all 50 welders!

Bottom Line - - "Some extra

gas flow at the start is very beneficial." In addition, after about a year

of use their gas supplier called to see if their business had turned down since

they were using about 30% less gas- it had not!

Second Case: A review of the shielding gas

flow rates in a shop with 100 welders revealed the amount of excess gas flow

on each welder.

DETAILS: A shop with ~100 MIG welders tried to

reduce gas waste by installing flowmeters with flow controls at the wire feeders. These were connected by a gas

hose to a 50 psi shielding gas pipeline. Most of the flowmeters were model L-32

(shown at right) which is designed to read accurately at 50 psi inlet

pressure, so the flow readings

are direct and accurate. by installing flowmeters with flow controls at the wire feeders. These were connected by a gas

hose to a 50 psi shielding gas pipeline. Most of the flowmeters were model L-32

(shown at right) which is designed to read accurately at 50 psi inlet

pressure, so the flow readings

are direct and accurate.

As when mounting a flow control orifice at the wire

feeder, this approach eliminates the start surge flow but there is insufficient

extra gas available to purge air from the weld start area and

MIG gun nozzle. It is if you're starting in air! As expected,

the welders tried to compensate by increasing the steady state flow! However increasing the steady state flow can only partially help as a substitute for quickly needing extra gas at the weld start! it also wasted much more gas than moving the flowmeter to the wirefeeder reduced!

The following was observed:

|

~50% of the welders were set at ~50

to 55 CFH. None were found lower than that flow level. |

|

~25% of the welders were set near the

top of the flowgauge, which for this model is 70 CFH. |

|

The remaining ~25% had the flow ball

pinned to the top of the flow tube. In our Lab we have measured

flows with this model of 150 CFH when the needle valve is fully opened and

the float ball pinned to the top of the flow tube! |

Conclusion:

Trying to compensate for the lack of sufficient extra start gas, the welders

set the steady state flow far higher than needed. Any flow over 50 to

60 CFH is also pulling air into the gas stream and is counter productive! Therefore increasing the steady state flow to the average 60 to 70 CFH observed, increased gas usage far more than the observed decrease in initial gas surge!!

|

|

Question:

But we use a flow control orifice just to limit start surge flow and still

control the steady flow with a flowmeter at the gas source. Is that a

problem?

Answer:

That will eliminate

the problem of excess gas surge but depending on the orifice size may not

supply sufficient extra gas. We have found most commercially available

peak flow control orifices are actually not large enough to optimize start

surge flow rate. In addition you may be doing that since you perceive

your saving gas. You can hear the reduction that occurs in initial gas

surge, right? Yes the surge flow is reduced and you can hear the difference. However if you put a pressure gauge in

the gas

delivery hose, you will see it still reaches the pipeline pressure (or with

cylinder gas supply the regulator pressure) when welding stops! The

pressure will reduce to what is needed to flow the required amount of gas

when welding starts (usually about 4 or 5 psi.) Where does that

extra gas go? It is wasted almost as if you did not have the orifice

in place! It just takes longer to be expelled at the rate set by the

orifice! You may save some gas, may 10% of the surge waste. Our

GSS saves about 80% of the gas waste!

It pays for itself in a matter of weeks and includes, as part of its

patented design, a surge flow limiting orifice at the feeder/welder end.

Check it out

Want More Details

About Extra Gas Needed at Weld Start? |

| See Other

Questions and Answers; Click Link Below: |

|

Q&A About Ideal Gas Delivery Systems |

|

Q&A About Automatic Flow Compensation |