|

|

Page 1 of 5

HISTORY OF SUBMERGED ARC WELDING

One of the most significant welding processes invented and

widely employed throughout the world is Submerged Arc welding. Many of the

welded products which utilized this process contributed to significant changes

in the way we live, namely: |

- Large girders for modern long span bridges

- Massive beams needed for tall buildings

- Electric Power Generation:

- Penstocks to transport water from dams through water

turbines

- Steam boilers, piping, turbines

- Nuclear vessels

- Wind turbine towers, transmission towers

- Petrochemical vessels and piping

- Chemical processing vessels

- Ships and submarines

- Railroad cars and locomotives

- Large presses and machine bases

- Natural gas and oil pipelines

- Offshore drill rigs

- Large diameter water pipe

- Many other heavy plate structures

- Thinner material products such as water heaters and

propane tanks

- Hardfacing for steel mills, earthmoving equipment, mining,

etc.

|

|

SOURCES OF INFORMATION

Several publications have summarized the sequence of events

that led to the development of the Submerged Arc process. Not all are

accurate. Fortunately a search of the US patents and a book by R.D. Simonson can set the record straight. The writer also has the benefit of

knowing and working with some of the persons directly involved with the process

development. Documentation of the facts presented is given with patent numbers,

references and photographs. It is suggested students search the US Patent

Record using the patent numbers provided. It is available for patents

issued from 1790 free of charge on the Internet. Often other patents than

those mentioned can be obtained by looking at those sited in subsequent patents.

ALL PUBLICATION RIGHTS AND MATERIAL PRESENTED ARE THE SOLE

PROPERTY OF WA TECHNOLOGY, LLC, AND SHOULD NOT BE COPIED WITHOUT WRITTEN

PERMISSION.

ANYONE IS FREE TO MAKE ONE COPY FOR PERSONAL

USE. THIS CAN INCLUDE ONE PHOTOCOPY, ONE PRINTED COPY, AND ONE EMAIL COPY. THIS

INCLUDES USE BY A STUDENT FOR AN ACADEMIC PURPOSE.

|

|

THE

BEGINNING

Submerged

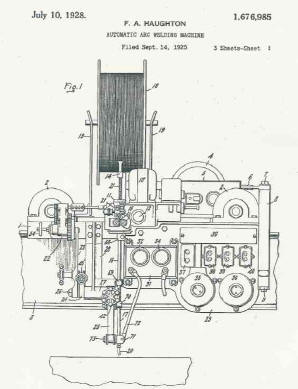

Arc was not the first automatic welding process. Patents dating in the early

1920’s describe automatic welding processes. As an example, US Patent number

1,676,985 by Haughton assigned to the General Electric Corporation was filed in

September 1925. [File dates rather than patent issue dates will be quoted as

these are the first record of an invention]. An insert of the drawing from

the patent is shown on the left. As noted it is an elaborate devise for

automatic welding with a continuous bare wire feed from a reel to the weld

zone. The unique feature defined in this patent is the use of oscillation of

the wire in the joint to be welded. However, as with a number of other machine

patents of the era, it was used with an open arc in air. Other references note

the welds from this simple process contained porosity and were not suitable for

many applications. One stated that even with an improved version of the open

arc in air process, a manual weld made with covered electrode (SMAW) would be

used inside a vessel to prevent leaks. Other automatic processes of the time

used coated rods where the coating was slit as the weld progressed to allow

current to be transferred at a fixed point from the work. As with open arc

processes weld current was limited and weld quality often poor. Submerged

Arc was not the first automatic welding process. Patents dating in the early

1920’s describe automatic welding processes. As an example, US Patent number

1,676,985 by Haughton assigned to the General Electric Corporation was filed in

September 1925. [File dates rather than patent issue dates will be quoted as

these are the first record of an invention]. An insert of the drawing from

the patent is shown on the left. As noted it is an elaborate devise for

automatic welding with a continuous bare wire feed from a reel to the weld

zone. The unique feature defined in this patent is the use of oscillation of

the wire in the joint to be welded. However, as with a number of other machine

patents of the era, it was used with an open arc in air. Other references note

the welds from this simple process contained porosity and were not suitable for

many applications. One stated that even with an improved version of the open

arc in air process, a manual weld made with covered electrode (SMAW) would be

used inside a vessel to prevent leaks. Other automatic processes of the time

used coated rods where the coating was slit as the weld progressed to allow

current to be transferred at a fixed point from the work. As with open arc

processes weld current was limited and weld quality often poor.

|

|

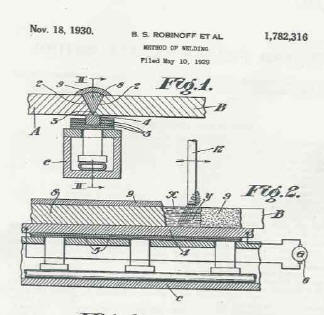

ROBINOFF PATENT

The use of

open arc automatic processes provides an appreciation of why the Robinoff patent

was considered as an advancement. Although often quoted as the “invention” of Submerged Arc, a careful

review will show it was in fact not! The patent, number 1,782,316, was filed in

May of 1929. The patent Specification and even Figure 2 (show at left)

show

what amounts to a relatively small amount of flux (by Submerged Arc standards)

being applied in the joint. Further on Page 1, Lines 40 to 44 in the

Specification it states: “The groove is then filled with a powdered scale

(ferrous oxide) to make the flux magnetizable.” On page 2, on Lines 43 to 48 in

states; “…the welding current will flow …through the rod and will become

magnetized so as to attract the flux 9. Their final claim, number 8 states;

“...moving the metal electrode … and drawing an arc causing said flux to

melt...” As will be mentioned later, if this were truly

a Submerged Arc they

would have the same difficulty as the inventors, i.e. Kennedy et al in defining

if there was an arc and would have at least not mentioned the presence of one!

However no doubt since there could be questions raised in any patent

litigation, Linde purchased the rights to this patent as well as those that were

significant. R.D. Simonson, in his book

“The History of Welding” (reference 1) pages 140 and 141 states; “Then the

Western Pipe and Steel Company called (referring to Harry Kennedy) for help with its Robinoff welding

process. Kennedy’s notes indicate that the problem there was attacked through

the welding flux being used. It soon became apparent this was no minor problem,

but one which, if it could be solved, would lead to the development of a basic

new welding process. Simonson further states on page 141; “Thus when the

business relationship between Kennedy and the Western Pipe and Steel Company

became mutually unsatisfactory in the early thirties the way was open for the

Linde Air Products Company to enter the picture. Linde’s recognition of the

value of the process at this early stage led to its commercial introduction in

1935 as the “Unionmelt” process.” The use of

open arc automatic processes provides an appreciation of why the Robinoff patent

was considered as an advancement. Although often quoted as the “invention” of Submerged Arc, a careful

review will show it was in fact not! The patent, number 1,782,316, was filed in

May of 1929. The patent Specification and even Figure 2 (show at left)

show

what amounts to a relatively small amount of flux (by Submerged Arc standards)

being applied in the joint. Further on Page 1, Lines 40 to 44 in the

Specification it states: “The groove is then filled with a powdered scale

(ferrous oxide) to make the flux magnetizable.” On page 2, on Lines 43 to 48 in

states; “…the welding current will flow …through the rod and will become

magnetized so as to attract the flux 9. Their final claim, number 8 states;

“...moving the metal electrode … and drawing an arc causing said flux to

melt...” As will be mentioned later, if this were truly

a Submerged Arc they

would have the same difficulty as the inventors, i.e. Kennedy et al in defining

if there was an arc and would have at least not mentioned the presence of one!

However no doubt since there could be questions raised in any patent

litigation, Linde purchased the rights to this patent as well as those that were

significant. R.D. Simonson, in his book

“The History of Welding” (reference 1) pages 140 and 141 states; “Then the

Western Pipe and Steel Company called (referring to Harry Kennedy) for help with its Robinoff welding

process. Kennedy’s notes indicate that the problem there was attacked through

the welding flux being used. It soon became apparent this was no minor problem,

but one which, if it could be solved, would lead to the development of a basic

new welding process. Simonson further states on page 141; “Thus when the

business relationship between Kennedy and the Western Pipe and Steel Company

became mutually unsatisfactory in the early thirties the way was open for the

Linde Air Products Company to enter the picture. Linde’s recognition of the

value of the process at this early stage led to its commercial introduction in

1935 as the “Unionmelt” process.”

|

|

Page

1

2

3

4

5(last) 1

2

3

4

5(last)

Have a Welder?

Improve Weld Starts and Have Shielding Gas Cylinder Last at Least Twice as

Long!

Note: Our Patented

GSS

is Not Available in "Stores"

A home shop fabricator

in Georgia with a Miller TM 175 amp welder

purchased a 50 foot Gas Saver System ( GSSTM

) so he could use a larger cylinder

and mount it on the wall of his shop. He wrote:

"The system works great.

Thanks for the professional service and

a great product."

Click To See His Home Shop

A Professional

Street Rod Builder Had This to Say:

With their standard MIG welder gas delivery hose the peak shielding flow at

weld start was measured at 150 CFH. That caused air to be sucked into the

gas stream causing poor weld starts. With the

GSS replacing their existing hose, the peak flow surge at the

weld start was about 50 CFH. Total gas use was cut in half. With their standard MIG welder gas delivery hose the peak shielding flow at

weld start was measured at 150 CFH. That caused air to be sucked into the

gas stream causing poor weld starts. With the

GSS replacing their existing hose, the peak flow surge at the

weld start was about 50 CFH. Total gas use was cut in half.

Kyle Bond, President, quickly saw the improvement achieved in weld start

quality as a significant advantage! Kyle, an excellent automotive painter,

was well aware of the effects of gas surge caused by pressure buildup in the

delivery hose when stopped. He has to deal with the visible effects in the

air hose lines on the spray gun in his paint booth! The paint surge is

visible and creates defects unless the gun is triggered off the part being

painted! We can’t do that with our MIG gun!

GSS

Customer Testimonial: PDF Download

See

Video Showing What Users Say About Our Gas

Saver System-CLICK

Here or Picture See

Video Showing What Users Say About Our Gas

Saver System-CLICK

Here or Picture

▲HOME

►CONSULTING

SERVICES |

|

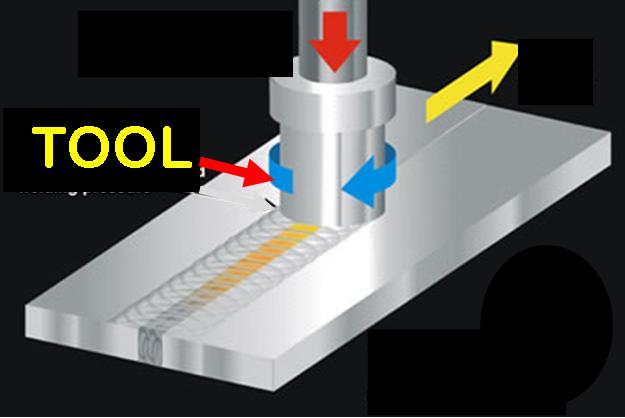

New

Info-"Friction Stir Welding"

|

|

|