|

WELDING “HEAT TREATED” 4130

(QUENCHED

AND TEMPERED) Chrome Moly (Chromoly)

|

Pronouncing Chrome-Moly Pronouncing Chrome-Moly

I always pronounce it as Chrome-Moly. Not, cromoly, pronounced like two animals!

CLICK to SEE DETAILS: |

|  Video-Welding 4130

CrMoly Video-Welding 4130

CrMoly

|

|

Alert !!

Argon Prices Have More than Doubled in Past Several Years!

Two European companies have bought key US Industrial Gas Companies, Airgas and Praxair. They now have 77% of the North American Argon production! Prices will go higher!

See a

Video

or Download a PDF Report showing why the price increase and the reason a

major Argon and Helium Producer and a leading Airplane

Manufacturer purchased 300 of our patented Gas Saver Systems for

their TIG Welders to cut gas use

up to half, by reducing waste! |

|

This

web page presents information about welding

heat treated,

high strength

4130 Chrome Moly tubing for race car frames where no post weld heat

treatment is utilized. We are not advocating this be done, in fact in

most cases just the opposite.

The reason for discouraging welding

heat treated, high

strength

4130 tubing without subsequent appropriate heat treatment

(meaning heating the finished weldment to 1600 F,

quenching in oil or water and then tempering to 1000 to 1150 F) is that the

area next to the weld will have much lower

strength and

may contain some brittle

areas!

We’re presenting this

information because of issues with:

-

AA Fuel Dragsters being allowed to use

higher strength, heat

treated 4130 and increased stresses for some frame members. (Cory McClenathan crashing at Bristol, Tenn. apparently

because of excessively thin wall frame tubes that

experienced local buckling at 300 mph!)

-

Some Funny Cars where Heat Treated

4130 apparently had been used and the chassis broke in what reportedly appears to be

a brittle manner.

-

Questions received in technical talks at

American Welding Society meetings and emailed to our Web Site from

race car and custom motorcycle frame builders wanting to use this higher

strength -"stiffer" material (when it is NOT stiffer!)

-

A recent article in a popular car

magazine which reinforced the need to define that increased “strength”

Does Not Mean “increased

stiffness!”

A Definitions Page is

provided to keep this discussion of reasonable length. Just click on the

words in

bold italics

to obtain a non

metallurgist definition.

Note: If your going to

"heat treat" the

finished welded 4130 part (by heating to 1600 F, quenching in

oil or water and then tempering to about 1100 F) see comments from my original Article published in

The American Welding

Societies Journal and quoted on this web site page. |

|

WHY 4130 IS STRONGER WHEN “HEAT TREATED”

Also, Why Recommended Welding Rod and

Procedures for Welding Normalized 4130 Cannot be Used to Solve the Problems

That Can Occur When Joining Heat Treated Material.

In the mid 1970’s, while managing a welding

shielding gas, MIG wire, TIG rod R&D Laboratory, I received a call from

a dragster chassis manufacturer requesting a recommended TIG rod for joining

normalized

4130. They did not plan to use preheat or any post weld

heat treatment. To minimize the chances of weld cracking when mixed with this

high carbon (by welding standards) 4130 material, a low carbon AWS ER70S-2 TIG rod

was recommended. This alloy rod has become widely

accepted as an excellent solution and has proven successful over many years. Welding

heat treated 4130

has totally different implications. The area next to the weld, not just the

weld metal, becomes the critical issue. In the mid 1970’s, while managing a welding

shielding gas, MIG wire, TIG rod R&D Laboratory, I received a call from

a dragster chassis manufacturer requesting a recommended TIG rod for joining

normalized

4130. They did not plan to use preheat or any post weld

heat treatment. To minimize the chances of weld cracking when mixed with this

high carbon (by welding standards) 4130 material, a low carbon AWS ER70S-2 TIG rod

was recommended. This alloy rod has become widely

accepted as an excellent solution and has proven successful over many years. Welding

heat treated 4130

has totally different implications. The area next to the weld, not just the

weld metal, becomes the critical issue.

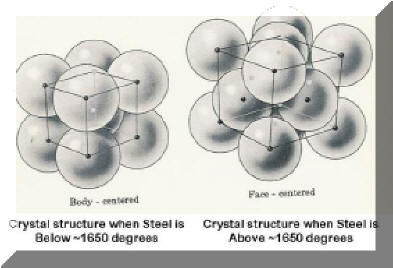

The

reference to

heat treated steel generally means the material is heated to a

temperature where a structural change occurs in the crystal lattice.

In the case of 4130 about 1600 degs F. At these temperatures the iron atoms have

a Faced Centered

cubic

arrangement (right in the figure above) and carbon atoms are interspersed between. If

cooled slowly, the atoms will rearrange to a low stressed

Body Centered

cubic

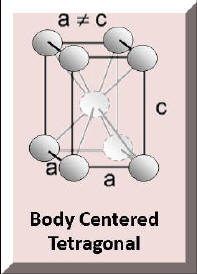

state (left in figure.) However if quickly

quenched

from 1600 F the structure does not realign to a

Body Centered

cubic structure but rather a

Body Centered

Tetragonal arrangement

(as noted in accompanying figure one side of the rectangle is shorter than

the other so it is not a cube) leaving a very

highly stressed material which is very

hard and strong. This

metallurgical structure is called

Martensite (named after metallurgist Adolf

Martens.) The resulting

tensile strength

could be in the range of 250,000 psi. Unfortunately it is

also very brittle.

What does brittle

mean? It means this very strong steel can act like glass when subjected

to a sharp blow or highly stressed environment! A positive term used to

quantify a steels resistance to brittle failure is a property called

toughness.

One measure of toughness is the Charpy test (although not useful for

very

thin material its valuable

to understand the

Charpy test.) The photo below left shows two broken Charpy test specimens.

The lower two matching pieces shows how

brittle

steel looks. There was little energy required to initiate and sustain the

fracture. The upper broken specimen shows the deformation that took place at

the outer edges and the matt finish in the center requiring more energy to

break the Charpy bar. To reduce this

brittleness, the quenched and hardened steel can be

tempered.

Tempering

requires reheating the very

quickly cooled steel to usually 700 to 1100 degs F. For gears and items

that need to be

hard, and that will operate at higher temperatures, a low tempering

temperature may provide enough

toughness.

However for 4130 used in structures, the

tempering

is usually done at about 1000 to 1100 degs. F to provide acceptable resistance

to brittle

failure. At these

tempering Tetragonal arrangement

(as noted in accompanying figure one side of the rectangle is shorter than

the other so it is not a cube) leaving a very

highly stressed material which is very

hard and strong. This

metallurgical structure is called

Martensite (named after metallurgist Adolf

Martens.) The resulting

tensile strength

could be in the range of 250,000 psi. Unfortunately it is

also very brittle.

What does brittle

mean? It means this very strong steel can act like glass when subjected

to a sharp blow or highly stressed environment! A positive term used to

quantify a steels resistance to brittle failure is a property called

toughness.

One measure of toughness is the Charpy test (although not useful for

very

thin material its valuable

to understand the

Charpy test.) The photo below left shows two broken Charpy test specimens.

The lower two matching pieces shows how

brittle

steel looks. There was little energy required to initiate and sustain the

fracture. The upper broken specimen shows the deformation that took place at

the outer edges and the matt finish in the center requiring more energy to

break the Charpy bar. To reduce this

brittleness, the quenched and hardened steel can be

tempered.

Tempering

requires reheating the very

quickly cooled steel to usually 700 to 1100 degs F. For gears and items

that need to be

hard, and that will operate at higher temperatures, a low tempering

temperature may provide enough

toughness.

However for 4130 used in structures, the

tempering

is usually done at about 1000 to 1100 degs. F to provide acceptable resistance

to brittle

failure. At these

tempering

temperatures a fully

quenched

and tempered

(Q&T) 4130 will have

strength of about 150,000 psi but will have higher

toughness

and ductility

than the as

quenched

material. temperatures a fully

quenched

and tempered

(Q&T) 4130 will have

strength of about 150,000 psi but will have higher

toughness

and ductility

than the as

quenched

material.

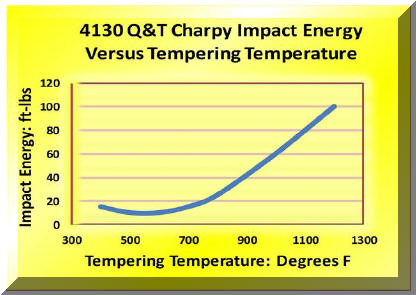

There is a

tempering temperature

range between 500 and 700 degrees where the steel may not improve

and may even reduce somewhat in toughness. This

reheat range should be avoided (see graph below.)

In the weld

Heat Affected Zone (HAZ) we can't avoid reheating the tubing from

a temperature close to the melting point of the steel, 2500 deg F, to temperatures in and below

that range which will decrease the strength! Tempered

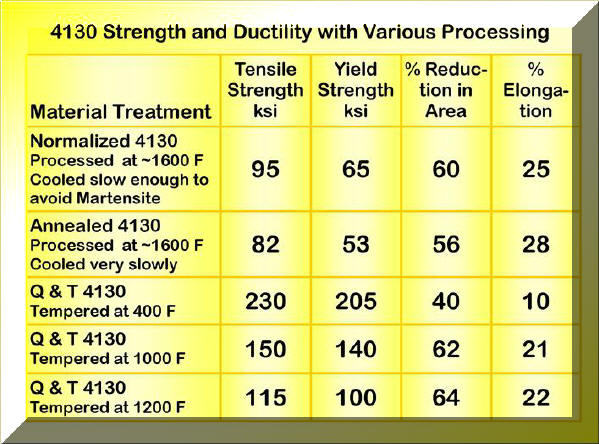

properties are also dependent on

tempering time. The following table presents

the strength of 4130 after various heat treatments:

|

|

|

|

Note the

strength can be reduced after

heat treating

to 115 ksi (Note 1 ksi = 1000 psi) by

carefully reheating to 1200 F. The exact temperature and time are very

important. Heating with a torch can not assure the proper desired

properties.

The

graph left shows the resulting

toughness

after tempering to specific

temperatures. Note there is a low

tempering temperature

where the

toughness

does not increase and may actually

decrease. The

graph left shows the resulting

toughness

after tempering to specific

temperatures. Note there is a low

tempering temperature

where the

toughness

does not increase and may actually

decrease.

CAUTION:

When welding

heat treated,

Q&T 4130 the area adjacent to the weld deposit (Heat Affected Zone)

will reduce in strength.

|

|

WELD HEAT

AFFECTED ZONE PROPERTIES

Weld metal chemistry can be controlled by

the type of welding filler rod/wire used. The amount of base material melted into the weld

deposit must also be

considered. When very small fillet welds are made in 4130 tubing the

large amount of melted high carbon (by welding standards) base material in the

weld deposit can significantly increase weld

strength. That is why we

recommended AWS ER70S-2 when welding normalized

4130. It has very low,

0.06 carbon so when mixed with the 0.33 carbon in the 4130 the weld deposit carbon content is at a

lower level, less susceptible to

cracking.

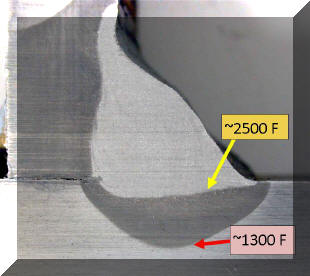

Where the melted weld properties are

influenced by the rod/wire selection, they have no influence in the area next to the weld called the

Heat Affected Zone (HAZ.) In the photo left, the

weld and

HAZ are revealed by chemical

“etching” a cross section. The outer etching boundary is

defined as a line that reached about 1300 degrees F. The line exists

because a metallurgical change occurs in steel at that temperature. Therefore

the visible

HAZ was

heated to a temperature from about the melting point of the steel (about

2500 degs F) next to the weld through this 1300 deg F line then on to 500 F

and lower. The width of the

HAZ area will be

larger when welding thinner materials. If

previously

quenched

4130 is

tempered

to 1050 degs F to

achieve the desired properties, we have essentially

tempered

the tubing next to the weld from 2500 degs F all the way down to the 1050

degs F! The time

at temperature is also a factor and will depend on weld heat input, wall thickness etc. In

general, the

HAZ will have a

strength much less than the “after tempering” 150,000

psi, for example! In fact that area will probably be no stronger than if we welded the more

typically used normalized

4130 tubing.

Normalized 4130 tubing was cooled more slowly from a high temperature,

never creating the

hard, brittle

Martensitic

structure and it is also much tougher

than the as-quenched

material.

Normalized 4130

usually has a

strength

of about 95,000 psi.

The mixture of metallurgical structures present in the

HAZ of welded

Q&T

4130 may contain some

brittle areas. Where the melted weld properties are

influenced by the rod/wire selection, they have no influence in the area next to the weld called the

Heat Affected Zone (HAZ.) In the photo left, the

weld and

HAZ are revealed by chemical

“etching” a cross section. The outer etching boundary is

defined as a line that reached about 1300 degrees F. The line exists

because a metallurgical change occurs in steel at that temperature. Therefore

the visible

HAZ was

heated to a temperature from about the melting point of the steel (about

2500 degs F) next to the weld through this 1300 deg F line then on to 500 F

and lower. The width of the

HAZ area will be

larger when welding thinner materials. If

previously

quenched

4130 is

tempered

to 1050 degs F to

achieve the desired properties, we have essentially

tempered

the tubing next to the weld from 2500 degs F all the way down to the 1050

degs F! The time

at temperature is also a factor and will depend on weld heat input, wall thickness etc. In

general, the

HAZ will have a

strength much less than the “after tempering” 150,000

psi, for example! In fact that area will probably be no stronger than if we welded the more

typically used normalized

4130 tubing.

Normalized 4130 tubing was cooled more slowly from a high temperature,

never creating the

hard, brittle

Martensitic

structure and it is also much tougher

than the as-quenched

material.

Normalized 4130

usually has a

strength

of about 95,000 psi.

The mixture of metallurgical structures present in the

HAZ of welded

Q&T

4130 may contain some

brittle areas.

|

|

WHAT HAPPENS WHEN WELDED Q&T 4130 IS STRESSED?

When the structure is stressed, the

~150,000 psi strength

tubing material will

have a much weaker (perhaps 90,000 psi)

HAZ area between

the joined pieces.

The strength will be reduced in the

HAZ in a band heated from the 2500

degs F area next to the weld all the

way down to a band that reaches the 1050 degs F

tempering

temperature. That weakened band could be wide in

deposits made in thin wall tubing as shown in the photo right.

Note the area that reached 1000 deg F is further away from the weld than the

visible 1300 F outer etching bounder. It addition, if any brittle

metallurgical constituent exists, cracks may form and propagate in the

highly stressed HAZ even at

lower overall stress levels. Because of the lower strength in the

HAZ our usual suggestion

(which has proven successful for many years) of using an very ductile AWS ER70S-2

welding rod and making slightly larger fillets to compensate for the somewhat lower

strength

will not help a weak (with some potentially brittle areas) HAZ!

strength

tubing material will

have a much weaker (perhaps 90,000 psi)

HAZ area between

the joined pieces.

The strength will be reduced in the

HAZ in a band heated from the 2500

degs F area next to the weld all the

way down to a band that reaches the 1050 degs F

tempering

temperature. That weakened band could be wide in

deposits made in thin wall tubing as shown in the photo right.

Note the area that reached 1000 deg F is further away from the weld than the

visible 1300 F outer etching bounder. It addition, if any brittle

metallurgical constituent exists, cracks may form and propagate in the

highly stressed HAZ even at

lower overall stress levels. Because of the lower strength in the

HAZ our usual suggestion

(which has proven successful for many years) of using an very ductile AWS ER70S-2

welding rod and making slightly larger fillets to compensate for the somewhat lower

strength

will not help a weak (with some potentially brittle areas) HAZ!

|

|

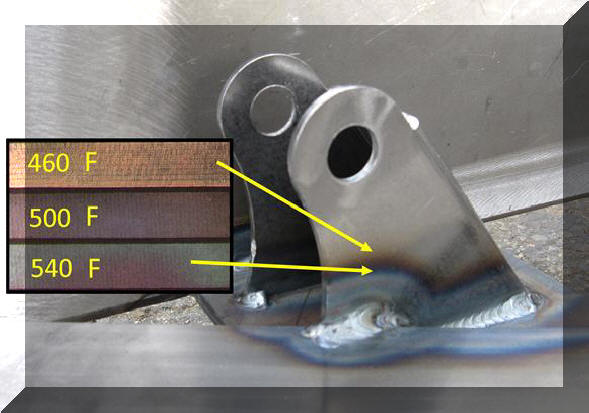

An interesting way to see what temperatures are reached when

a weld was made is on a sand blasted surface is shown in the above

photo. Steel oxidizes to specific colors depending on the temperature

reached. These are called temper colors. This photo shows how far from the weld

the plate reached 500 F while welding.

|

|

STIFFNESS

Why use “high

strength”

4130 in the first place? All else being equal 250,000 psi oil/water

quenched

4130 tubing is no ”stiffer” then mild steel with 50,000 psi

tensile

strength! Both will bend the same amount when loaded (assuming the

structure does not take a permanent set or what is referred to as yield.) This assumes the same tubing

diameter and thickness are being compared. Generally when switching from a lower strength

material, for example mild steel at 50,000 psi to 4130 at 95,000 psi tensile

strength, a different size tube will be employed. Refer to the web page

of properties and metallurgical definitions under the section on

stiffness, to understand what needs to be done to achieve

a “stiffer” structure. 4130 Chrome Moly is also the same weight

per cubic inch as mild steel. The only way it can be stiffer and lighter is to use large diameter tubing with a thinner wall thickness.

SUGGESTIONS

What Should be Done to Join Heat Treated

4130?

First be sure it is understood why the

higher strength

is being used. If there is a real structural benefit or are you just

getting into and area where

local buckling

may occur? If the extra

strength is a real benefit, then perhaps welds can be

placed in an area of lower stress. Other joining techniques can also be

considered. Racing bicycle manufactures use special brackets or "Lugs" that capture

the tubing and then they braze the joints at much lower temperatures than

caused by welding. You could

also heat treat the final product. It is very difficult to take a

complex fabricated chassis, heat the assembly (with the needed fixture

to minimize distortion) to 1600 deg F, then quench in

oil and have it remain in the desired shape! However one Baja race car team

reports they were going to do just that. Not sure how they managed the inevitable

distortion or if it was a successful approach!

|

|

SIDE BAR

An interesting

analysis was developed from information presented on Metallurgical

Technologies' web site. They examined a weld made in 4140 steel which has

0.40 carbon. This steel is more hardenenable than 4130 meaning at

typical TIG welding cooling rates it can produce 100% hard, brittle Martensite in

parts of the HAZ. This is what appears to have occurred in this weld.

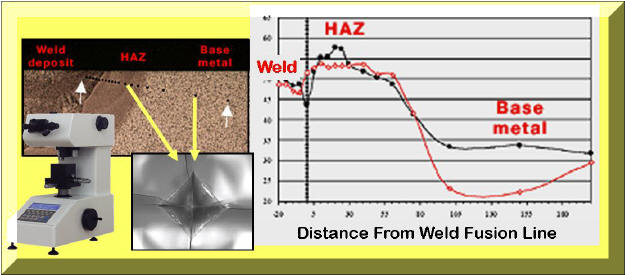

Two microhardness traverses of the Weld, HAZ and Base Metal are presented in the above graph

(typically these are taken near the top and center of a welded section.).

Converting the hardness data shown on the black line to approximate tensile strength; the unaffected Base Metal was ~150 ksi tensile

strength and the weld much harder with a equitant tensile of ~240 ksi.

The HAZ next to the weld had a hardness equivalent to ~300 ksi.

The base material may have been quenched and then tempered to about 1100 F to

achieve 150 ksi tensile strength. Mechanical property data for 150 ksi

Q&T

4140 shows it may have a reasonable Charpy toughness of ~60 ft-lbs. When

tempered to only 400 F it will have a tensile of ~260 ksi and only a brittle,

10 ft-lbs Charpy impact toughness. The ~300 ksi HAZ toughness would be even lower -"glass like!" In addition, the

hardness traverse shown on

the red line indicates a dip in strength to the equivalent of 110 ksi.

This probably occurred in an area that was subjected to a slower cooling

rate and reached a temperature above the original tempering temperature. To

reduce the HAZ strength and improve ductility in this 4140 weld, a minimum

preheat of 400 F or higher should be used even for thin material to

lower the cooling rates sufficiently to avoid the formation of Martensite.

Note, 4140 steel is

about twice as hardenable as 4130. This means a weld cooling rate that

is sufficiently slow to just avoid producing Martensite in a 4130 HAZ can

produce a 100% Martensitic structure in the HAZ of 4140 steel (See

Note Below.) With its lower,

0.30 carbon 4130 is less likely to have a brittle HAZ but if welding

heat treated, higher strength 4130 the HAZ will decrease in strength. Although 4130

presents

less of a HAZ problem then 4140 when welding Normalized material, if welding higher strength, heat treated

4130 a hardness traverse will define the approximate amount of strength

reduction and is

a method to evaluate weld procedures and HAZ properties.

The weld macro

section shown on the left of the above figure is not from their web site but

shows how a hardness traverse is made. A hardness testing device

incorporating a microscope (one type shown in white) is used employing a small

diamond indenter. The small black dots in the polished cross

section (seen between the white arrows) are the very small indentations made

with the hardness tester.

The magnified photo at the bottom shows their shape. The depth of the

indent with a fixed load is a measurement of hardness.

My recommendation is to have some

testing done by a competent metallurgical or welding research firm to

evaluate the quality of weldments in 4130.

With the amount of sponsor money spent on most racing series they surely can

be called upon to assist with researching weld quality and materials suitability

issues.

Email

for recommendations on hiring a firm.

Note:

As seen in a Continuous Cooling Diagram of 4130

(Click to See)

the nose of the graph is very close to TIG weld cooling rates in thin

material. With cooling rates that reach 900 F after about 5 seconds

little if any Martensite will be produced. With 4140 the nose of the

curve will be displaced

right to about 9 seconds. Even the slower TIG weld cooling rate shown

will produce Martensite in the HAZ. The cooling rate curves were

obtained using equations from the AWS Handbook; See

Calculations. |

|

"Advanced Automotive Welding"

Author: Jerry Uttrachi

(President of WA Technology)

This 176 page book includes detailed metallurgical information about

welding Chrome-Moly

CLICK for Book Details |

|

If higher strength

steel is felt necessary why not use an alloy that is strong, tough and more readily weldable like HY-130.

For More Information on Welding 4130

Chrome Moly:

Click for BASIC 4130 WELDING

DETAILS

Click for

TECHNICAL & METALLURGICAL DETAILS

Click for

EQUATIONS

Defining Weld Cooling Rate in Tubing

Click for

METALLURGICAL DEFINITIONS

Click for

DEFINING "EFFECTIVE HEAT INPUT"

Click for WELDING A BETTER

STEEL; HY 130 |

|

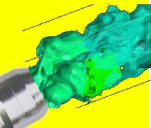

Improve Weld Starts

and Save Money by Eliminating The

"Gas Blast" at MIG Weld Starts That Causes: Improve Weld Starts

and Save Money by Eliminating The

"Gas Blast" at MIG Weld Starts That Causes:

1)

Inferior Weld Quality and Excess Spatter

- due to the air pulled into the gas stream

2)

Shielding Gas Waste

- typically 50% of gas used

See Patented

Gas Saver System (GSS)

Solution

GSS

Works for TIG Welders with Foot Pedal or Thumb Control

|

Stop

Wasting Shielding Gas!! Stop

Wasting Shielding Gas!!

See YouTube Videos

Including Our Patented MIG Shielding

"Gas

Saver System" (GSS)

Why MIG Gas Waste

Detailed Review of GSS

Short Overview of GSS-90 Seconds

What User Say About

GSS

Welding Race Cars

Rat Rods-Then and Now

Welding: Go Green

Engineering A

Pro Street / Street Rod

|

| |

|

MIG Gas Delivery and the Small Block Chevy

Evolved in a Similar Way and Time!

Both had Advances and

Setbacks Before

They Were Optimized!

Click

for a PDF Report on the Similarities |

Free Technical Paper, "MIG

SHIELDING GAS

CONTROL"

CLICK ICON for PDF DOWNLOAD |

|

Thanks to those "Car Crazy" folks who have purchased

the Gas Saver System and commented on the improved starts and reduced gas usage

they have achieved. Many purchased our 6 foot prefitted

GSS,

Part Number WAT FB6,

a 3 or 4 foot system, FB3 or FB4 are also available.

GSS

Customer Testimonial: PDF Download

ONE PAGE SUMMARY

PURCHASE

PRODUCT

FREE Corvette Accessory Installation Info

|

"WARNING: "Weld

Safely"

|

|