|

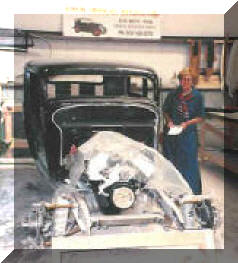

Gibbon Fiberglass

Was one of the best reproduction Ford body and parts builder

(unfortunately no longer in business). They always built

the body on the frame that will be used with the car. This made the

fit much easier to achieve and maintain. Here the sides, rear and top

are glassed together. Oak reinforcement is used since it more closely

matches the expansion rate of fiberglass than does steel. Of interest,

they use wood in about the same places as did Henry with the steel

originals! Wife Christine is checking out the progress. |

|

Getting Proper Clearance. The

secret of having 1/4 inch clearance around the ZZ 502 Big Block is the

firewall and floor pan are being laminated in sections to exactly fit

the engine set back and transmission. |

|

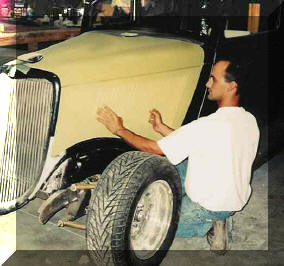

Getting Perfect Fit

Fitting doors and fenders requires a lot of patience and effort. You must

have the final wheels and tires if you expect the finished product to fit

and look right. |

|

Fitting Steel Hood

Scott

did most of the fitting and finishing.

Here he fits a Rootleb hood

with stock lovers on the side. That a good choice

(see Keep-Cool page) since it really helps get

the hot air out of the tight engine compartment! After several years

all the gaps remain very uniform and accurate. |

|

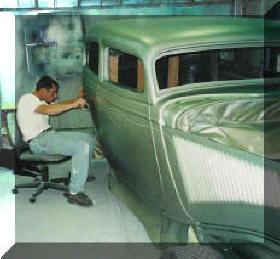

Sanding and Sanding After all the glass work is

completed, fenders and running boards fit it was time for many sessions of

block sanding and wet sanding before the high build primer was spayed on.

Then just more sanding again, however this time with finer and finer paper. |

|

Apply the Paint The

first thing painted is the underside of the car. The frame had

already been painted and looked too good to cover up. It's simple to

paint the bottom, just get the whole shop to help turn it over! |

|

The next steps are critical to the way Kyle Bond the

owner and master painter, did the flames. First several coats of the main

color are spayed. This was done on a Friday night since the clear coats

must be put on within 24 hours. First thing Saturday morning

the flames were started. Sketches were made and pictures of flames on other

cars collected but ultimately having seen Kyle's work, it was left up to him. |

|

Start Flames Kyle laid out the flames by hand with thin masking tape. After the

first side and hood were done he duplicated the pattern on the other side.

Now all the areas that were not to be painted with flames were masked. Lots of masking

paper was needed. |

|

Pin Strips The flames are "pin striped" on

one edge in black. First areas to be stripped are

spayed in black. It makes no difference that black paint

goes into other parts of the flame...since Kyle takes 1/8 inch masking tape and

covers the black where the stripes will be! All other black will be covered

in the dark silver. Note the back brace Kyle is wearing when he is doing the

fenders! This step took several hours. |

|

Spray Flames "Striping"

finished the darker silver flames were spayed.

After the paint set for 15

minutes all the pin "striping" tape was carefully removed. You could see the very

uniform sharp black edge of the flame. Then everyone could pitch in to

carefully remove

all the masking tape. |

|

Clear Coats You can see the gloss after one clear coat. It

was spayed 20 hours from the start of the project! Several

more followed. Note all the fenders were painted separately then assembled

at the end. At first we thought the flames would not stand out as much as

they do since the frame colors were not that distinctly different. However the

combination of the black "pin stripes" on one edge and the curved body

and fender shape which reflects the

light differently makes the final effort subtle but very noticeable. They

are not ghost flames. |

|

Car In Magazine We got lucky. When the car was finished being painted

and body parts assembled, Street Rod

Builder Magazine did a story on Gibbon. They took a photo of the car by going up in a fork lift! It came out great even though is was far from

finished. The photo on the left was taken from the January 2001 issue. |