The brakes were OK but

did feel spongy and had a long stroke, actuating close to the floor. Lived with that for

several years until I saw a TV program that talked about residual pressure valves and

what would happen if you didn't install them. The peddle would feel

spongy and go close to the floor. Hmm!

The brakes were OK but

did feel spongy and had a long stroke, actuating close to the floor. Lived with that for

several years until I saw a TV program that talked about residual pressure valves and

what would happen if you didn't install them. The peddle would feel

spongy and go close to the floor. Hmm!

Right after that

comment I recalled when I

was building the car I had noticed two residual pressure valves had been installed by

TCI in the rear brake lines - in series. I even called TCI and asked

if that would be OK. They said no problem. After all these years

was it possible they did not have a residual valve in the front line?

Quickly went to the garage and jacked up the car side. Sure enough

no front residual

valve!! They had installed two - but both in the rear line!

no front residual

valve!! They had installed two - but both in the rear line!

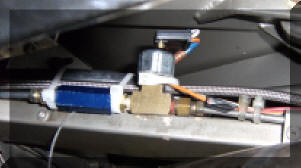

Fortunately Wilwood

sells a residual pressure valve with one standard brake fitting on one end and an

1/8" to 1/8" pipe fitting on the other (above photo.) This was perfect

to install on the Tee fitting that houses the brake light pressure switch!

No need to pull out my double flair fitting tool! Just removed the

brake line from the Tee fitting and installed the Wilwood Residual Pressure

Valve (see picture left.) Bending the original brake line to fit was

no problem.

That Was The

Solution! Better overall braking and a higher less spongy peddle.