CICK for Partner's Mobile Friendly Website

They're Offering FREE Shipping for GSS'

Improve MIG Weld Quality,

Improve MIG Weld Quality,

Cut Shielding Gas Use in Half;

by Reducing "Gas

Blast" Waste at Weld Starts

Improve MIG weld start "QUALITY," reduce start spatter and wasteful excess start gas, using patented Gas Saver System (GSSTM) Prices Start at $80. Over 15,000 in Use!

HAVE MORE THAN ~20 WELDERS? Email: Jerry_Uttrachi@NetWelding.com FOR SPECIAL PRICE

Ask About These Reports:

1) Why our patented GSS IS MUCH BETTER than FOOLISH "low pressure" supposed gas savers that sell for >$200, cause flow variations and can waste gas!

2) Why controlling flow at the welder or wire feeder doesn't work!3) Electronic pulsed gas control device that has a number of problems and costs >$1000!

4) How GSS reduces weld porosity due to moisture...

Links to Technical Reports and information:nks

Why Chart Industry Has Over 3000 GSSs installed

http://netwelding.com/Why_Chart_Has_3000_GSSs.pdf

7 Companies Report Improved Starts with GSS as Important as Gas Savings

http://netwelding.com/Start_quality_Improvement.pdf

12 Companies Quantify GSS Gas Savings

http://netwelding.com/Fabricators_GSS_Tests_Results.pdf

How Choked Flow Works and Test Results with Low Pressure Device

http://netwelding.com/Automatic_Flow_Control.htm

What Gas Flow Rate Should Be Used (with Chart)

http://netwelding.com/MIG_Flow_Rate_Chart.pdf

Why the High Cost for Argon Gas (and why it will get worse!)

http://netwelding.com/Why_High_Gas_Cost.pdf

Detailed Tech Paper on Shielding Gas Flow Control

http://netwelding.com/Shielding_Gas_Control_Download.pdf

Locking Flow Settings on Needle Valve Flowmeters

http://netwelding.com/Flow_Rate_Limiter.htm

Order Low Cost Patented GSS

http://netwelding.com/prod02.htm

GSS has 4 to 6 Times Less Moisture Permeability of Std Hose

http://Netwelding.com/Low_Moisture_Permeability_of_GSS.pdf

2 years ago. Since the few

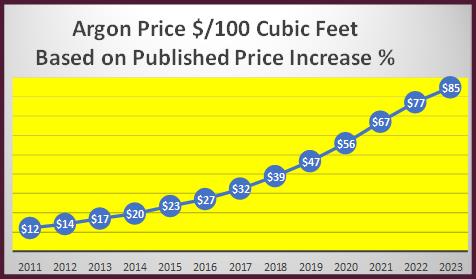

Argon Prices Doubled in Last Few Year.

CLICK to see why your gas supplier doesn't tell you how to cut gas waste and use

CLICK for PDF Report of Why High Argon Prices

e5,0 CLICK To See What Causes The Gas Blast? And How You Can Fix It:

Why Does Chart Industries Have Over 3000 Gas Saver Systems (GSS's) ?

Why Does Chart Industries Have Over 3000 Gas Saver Systems (GSS's) ?

A Caterpillar Tractor plant reported improved starts with less internal porosity with our Gas Saver Systems (GSS) installed on all their MIG welders. Savings in rework costs were as important than the substantial shielding gas waste reduction!

A Caterpillar Tractor plant reported improved starts with less internal porosity with our Gas Saver Systems (GSS) installed on all their MIG welders. Savings in rework costs were as important than the substantial shielding gas waste reduction!

See Case 2 Showing Details of Similar Reported Improved Starts

Download a FREE PDF of 7 Testimonials of GSS Weld Start Improvement

Download a FREE PDF of 7 Testimonials of GSS Weld Start Improvement

INDUSTRIAL TESTIMONIAL: Fabricator Cuts Gas Waste and Total Use Over Half!

A manufacturer of Truck Boxes welded 236 doors with one full cylinder of gas until it was empty to test gas savings. Just switching to a Gas Saver System (GSS) with NO other changes, i.e. same current, volts and gas flow rate, they welded 632 doors with 1 full cylinder.

A manufacturer of Truck Boxes welded 236 doors with one full cylinder of gas until it was empty to test gas savings. Just switching to a Gas Saver System (GSS) with NO other changes, i.e. same current, volts and gas flow rate, they welded 632 doors with 1 full cylinder.

That is a 63% gas savings. It would have required 2.7 cylinders to weld the 632 doors with their standard gas delivery hose. They purchased 25 systems for all their MIG welders.

About a year later they added 10 more MIG welding machines. Called and asked for 10 more of the "Magic Hose!"

Beau purchased a 4 foot long Gas Saver System (GSS) and reported these gas use results:

"I received the GSS in the early part of a large project, building a 12’ x 24’ steel building. Before installing it on my Miller 211C, I had completed about 30% of the total welds, and had consumed approximately 400 psi of my Argon/25% CO2 gas mixture. After Installing the GSS the remaining 70% of the welds required only an additional 300 psi consumption of gas. I more then doubled the number of welds, while reducing my gas consumption by 25%, I’d say the GSS is a real winner!

"I received the GSS in the early part of a large project, building a 12’ x 24’ steel building. Before installing it on my Miller 211C, I had completed about 30% of the total welds, and had consumed approximately 400 psi of my Argon/25% CO2 gas mixture. After Installing the GSS the remaining 70% of the welds required only an additional 300 psi consumption of gas. I more then doubled the number of welds, while reducing my gas consumption by 25%, I’d say the GSS is a real winner!Before I installed the GSS I was being stingy with the shielding gas flow, and the poor quality of my welds proved that. With the GSS installed I was confident that I was not wasting gas, and increased the gas flow rate. The result with that the appearance and quality of my welds improved dramatically. It not only saved shielding gas, but it increased my confidence. That’s a winning combination in my book!

Thank you for a wonderful product that actually does what you say it will."

Crunching the math for Beau Straley's gas usage: Over Twice The Welds Made/Used 75% of the Gas or 50%/75% = 67% Less Gas Used with GSS!

Including 11 fabricating shops in the USA, Chart Industries has over 3000 GSS's installed. They fabricate cryogenic tanks and natural gas liquefaction systems.

Including 11 fabricating shops in the USA, Chart Industries has over 3000 GSS's installed. They fabricate cryogenic tanks and natural gas liquefaction systems.

Chart China added 150 more GSSs in January 2020 for a total of 600. The Chart plant in the Czech Republic purchased 245 systems. A JV in India purchased 35 GSS's in 2019.

Bucyrus in China Repeated a GSS Order

A boom fabricator in China ordered another 250 GSS's in September 2019 after buying 250 systems prior.

Zamil

Steel in Saudi Arabia, uses CO2 shielding gas

and after consumption tests, bought 40 foot long GSS.

After 6 months, they purchased another 80 GSS.

Zamil

Steel in Saudi Arabia, uses CO2 shielding gas

and after consumption tests, bought 40 foot long GSS.

After 6 months, they purchased another 80 GSS.

AIC Steel Structures in Saudi Arabia, after installing 170 GSS's ordered ~100 more in 2018 and another ~50 in 2019!

In 2019 a Shipyard in the Philippines added to their previous purchase for a total of 140 GSSs.

ARGON PRICES Increased ~20+% about 2 years ago after Increasing ~35% the year before. Prices Have More Than Doubled in Past 5 Years!customer

Now that Airgas and Praxair have been purchased by a French and German company, another major producer owned by a Japanese company; the only other significant US Owned Argon Producer is Air Products (who have ~250 GSSs in their fab shops!). They only have about 18% of the US Industrial Gas Market. The three other foreign owner prodcuers have about 75%. The 2022 and 2023 price data (left) is from Annuall Reports that show very high growth rates. Air Products increased their dividend for the 41th striaight time in 2023..

Now that Airgas and Praxair have been purchased by a French and German company, another major producer owned by a Japanese company; the only other significant US Owned Argon Producer is Air Products (who have ~250 GSSs in their fab shops!). They only have about 18% of the US Industrial Gas Market. The three other foreign owner prodcuers have about 75%. The 2022 and 2023 price data (left) is from Annuall Reports that show very high growth rates. Air Products increased their dividend for the 41th striaight time in 2023..

Their ability to increase prices to cover costs+ is a key reason. ALL SUPPLIERS USUALLY FOLLOW WITH SIMILAR INCREASES.

STOP Wasting Gas; Prices will increase as supply will remain short. Can't just import gas for several reasons BUT it's also in short supply elsewhere. We have supplied hundreds of our patented Gas Saver Systems (GSS) to China, India Czech Republic and Saudi Arabia as well as many US fabricators.

Click Pic for PDF of Report on "Why Price Increases?"".

TESTIMONIAL: Received a second order from a fellow in Hawaii. Knowing things can be expensive, I asked about the cost of a cylinder fill! He responded:

TESTIMONIAL: Received a second order from a fellow in Hawaii. Knowing things can be expensive, I asked about the cost of a cylinder fill! He responded: “I’m just a weekend welder with a home shop. I have four 125 cubic foot tanks, two Argon and two 75 Argon/25 CO2. They cost $260 and $275 per tank to fill! With the Gas Saver System my weld starts look better and my gas saving's is 40%. Thanks for the fast shipping,”

A customer recently said, "I can't understand why every MIG welder doesn't use your great Gas Saver System (GSS)? Like the saying, Build a Better Mouse Trap and People Will

Beat a Path to Your Door."

A customer recently said, "I can't understand why every MIG welder doesn't use your great Gas Saver System (GSS)? Like the saying, Build a Better Mouse Trap and People Will

Beat a Path to Your Door."

I told him that only fits if they

know they have MICE!

Bottom Line:

If you are not using our low cost, patented GSS you have "mice!" It saves about half the shielding gas used by eliminating waste while improving start quality. Compared to other devices tried in the past, welders like the improved starts!! Over 15,000 GSS's are in use at industrial fabricators such as Air Products, Boeing, Caterpillar Tractor etc. See Partial User List.

"Flow Rate Limiter" - a Perfect Complement to Our GSS

Save Even More Gas With Our Patented Flow Rate Limiter (FRL)

The FRL is our latest shielding gas saving patent. It simply clamps on to and locks the flowmeter knob, preventing changes. No alterations are made to the flowmeter.

CLICK Here or Picture for Details.

Cut Shielding Gas Waste and Reduce Total Use by Over 50% with Our GSS and FRL

Questions & Answers:

We receive a number of questions about our "Gas Saver System" and shielding gas control in general. The following are some specific Questions:

Click Link to View Answer:

-

How Does Automatic Flow Compensation Work and Why is Over 25 psi Pressure Needed to Achieve it? Also See Video

-

Why Has My Gas Supplier Not Told Me About Excess Gas Flow Problems?

-

Why Simple Wire Feeder Mounted Orifices , Flowmeters, or Flow Control Regulators - Do Not Work to Reduce Gas Waste? Also See Video

-

What Problems Occur if Low Pressure Devices are Used to Reduce Surge?

-

What About Using Orifices To Control Flow at a Pipeline Gas Supply?

-

For Pipeline Gas Supply What Corrections In Flowmeter Readings Are Needed for Pressure Changes?

-

Can I use the Gas Saver System for TIG?

Have another question? Email Jerry_Uttrachi@NetWelding.com

Fabricator Installs 315 GSS in 6 Plants: Tests made in each plant, showed average 45% savings in total gas use. Click For Details

Major

Industrial Gas Producer purchases 235

GSS' s to weld cryogenic tanks.

Major

Industrial Gas Producer purchases 235

GSS' s to weld cryogenic tanks.

See Why Over Half The Shielding Gas Used is Wasted?

-

Check out a Fabricator Who Achieved 63% Shielding Gas Savings. Using our patented GSS They welded 632 parts with a full gas cylinder with their standard gas delivery hose they could only weld 236 identical parts!

-

Fabricator Documents significant Better Quality Weld Starts with our GSS.