|

Welding

Math (and Science) Welding

Math (and Science)

For Welders, Welding

Students, Welding Instructors and Others Involved in Managing Welding

Operations.

Understanding the fundamentals of how welding, particularly MIG welding, works and will assist in producing higher quality depositis and assessing

welding problems. If you are using or planning to use MIG Robotics welding this information is essential.

|

|

See Below: Why MIG Wire

Melts

Also See: 1) Gas Pressure Versus Volume:

Below;

2) Weld Cooling Rates;

3) Effective Heat Input;

4) Calculate Weld Metal Volume;

5) Weight of

Welding Wire / Foot; 6) How to Read a Ruler;

7)

Charpy Impact Variations Explained; 8)

Teacher Testimonials About Our Welding Math and Science Information: Below |

|

Welding Math and Physics PDF

|

See "Why Gas Waste"

Video |

| Video-Welding

Math & Science-Gas Flow Control-Part 1 |

Video-Welding

Math & Science-Gas Flow Control-Part 2 |

|

Video-Welding

Math & Science-Deposition & Penetration-Part 1 |

Video-Welding

Math & Science-Deposition & Penetration-Spread Sheet Part 2 |

|

Video- Science of

MIG Welding

Shielding Gas

Flow Control |

Welder Rap- -

on Gas Video |

|

Self

Study Program, Self

Study Program,

"Welding Math and Science;" 88 Pages, Part # WMS NOW a FREE pdf Downlod GOTO Purchase Page

This program provides basic information to help

welding students and welding supervisors understand welding process

characteristics using math and science. Includes and Appendix with

subjects like Reading a Ruler and Basic Math Functions.

CLICK to See Program Details

CLICK for Purchase Page

|

|

Received an Excellent

Question From A Recent Welding Student Who is Working as a Welding

Engineer and Watched Our, "Suggested MIG Gas Flow Settings" Video. He

Wondered How and Orifice or Needle Valve Can Automatically Set and Adjust to

the Proper Pressure to Maintain Consistent MIG Gas Flow?

The Answer is Much Longer

than the Question so a PDF was Produced:

Produced:

CLICK FOR

FREE PDF OF ANSWER: |

|

MIG WELDING

What Causes MIG Welding Wire to Melt?

This is the

question I ask when giving a technical talk on the subject. Many answers

are offered. Here is what it is

NOT; the “hot arc”, radiation from the arc or the wire passing

through the arc. Two phenomena are primarily responsible for wire melting. A

simple test will explain one of them:

-

BE VERY CAREFUL, ONLY CONDUCT THIS TEST WITH INSTRUCTOR

SUPERVISION--AND STAND BACK THE WIRE MAY "EXPLODE!!" (Use a Stick welder. With the machine turned off; clamp one

end of a 3 foot length of 0.035 welding

wire in a stick electrode holder and the other

under a work ground clamp . With the stick welder set

for 150 amps, turn it on (be careful to stand back). The wire will quickly

turn red, then white and then it will melt like a fuse. Note the short

time that took. That demonstrates one

of the causes

of wire melting during welding. As the wire

passes from the end of the torch contact tip to the arc, it is carrying all

the welding current and becomes very hot. It starts at room temperature

and can exceed 500 degrees F before the arc forms at the end (depending on the

"sickout," the distance between the tip and the workpiece.) wire in a stick electrode holder and the other

under a work ground clamp . With the stick welder set

for 150 amps, turn it on (be careful to stand back). The wire will quickly

turn red, then white and then it will melt like a fuse. Note the short

time that took. That demonstrates one

of the causes

of wire melting during welding. As the wire

passes from the end of the torch contact tip to the arc, it is carrying all

the welding current and becomes very hot. It starts at room temperature

and can exceed 500 degrees F before the arc forms at the end (depending on the

"sickout," the distance between the tip and the workpiece.)

-

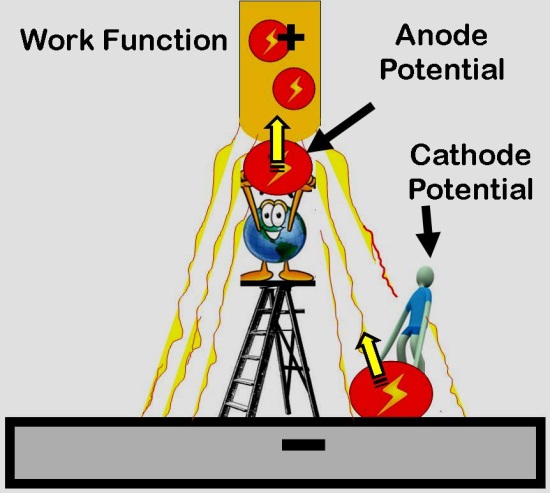

The second reason it melts is that current leaving or entering a surface, be

it wire or hot puddle, requires a given amount of energy for the electrons to enter or

leave that surface. This energy, generated at the surface, melts the already

hot wire. Therefore assuming Electrode Positive this is referred to as Anode

Potential (also called Work Function and measures as voltage) and is equal to the Amps

x Anode Voltage.

|

The

following equation obtained from Reference (1) defines the relationship: The

following equation obtained from Reference (1) defines the relationship:

Wire

Melting Rate (lbs/hr) = a x Amps + b x Wire Stickout x Amps 2

Where "a" and "b" are constants

and "Wire Stickout" is the

distance from the torch contact tip to the workpiece measured in inches.

(Note, constant b has been modified to compensate for the fact that this

equation was based on "Electrode Extension" that is measured from the

contact tip to the top of the

arc.)

The values for "a" and "b" for

0.035 inch diameter carbon steel wire are:

a =

0.017; b = 0.00014

These two energy sources cause the wire to melt. The first term (a x Amps)

is the anode voltage times current and the second term defines the energy input

due to resistance heating.

|

|

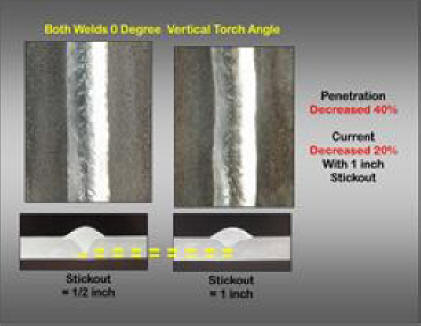

IMPLICATION OF THE EQUATION

One

of the major implications of this relationship is that an increase in the

stickout (at a fixed wire feed speed)

amperage will decrease. That has

a significant effect on another parameter, weld penetration.

(Note,

stickout is also called tip-to-work distance. The term

"Electrode Extension" or ESO is a more accurate measure of the

distance between the end of the contact tip to the top of the

arc. However for these calculations the stickout or contact tip-to-work

can be used and is easier to measure.)

Point of

Interest

The voltage you measure on a

MIG welder is a combination of the:

-

1) Small voltage drop due to

resistive heating of the wire (I2R)

-

2) The anode and cathode

potentials (that needed to get electrons out of the wire and into the puddle;

could be 1/2 the total measured)

-

3) The voltage drop across the

resistive arc.

|

|

WELD

PENETRATION

Weld penetration can be determined by a simple equation defined some years ago

by C. E. Jackson in Reference (2)

Weld

Penetration (distance into the base material when making a weld on plate

measured in inches) =

K [Amps4

/ (Weld Travel Speed; ipm x Volts 2)]0.333

For 0.035

inch diameter solid carbon steel wire, the constant K = 0.0019

Using these equations we find the following when we change wire stickout for

0.035 inch solid wire. Assuming a fixed wire feed speed that produces 200 amps

at 3/8 inch wire stickout:

|

Stickout, inches |

Amps |

Penetration

inches |

% Loss in

Penetration |

|

3/8 |

200 |

.127 |

base |

|

1/2 |

184 |

.114 |

11% |

|

5/8 |

172 |

.104 |

18% |

|

3/4 |

162 |

.096 |

24% |

|

7/8 |

154 |

.090 |

29% |

Note:

-

With a fixed wire feed speed the amperage

decreased from 200 amps with a 3/8 inch stickout to a low of 154 amps when the stickout was increased to 7/8 inches. The resistance heating of the wire

(the 2nd Amp2 term in the equation) is a very efficient heating process.

Therefore the current needed to finish melting the wire as it enters the arc,

becomes less as the wire is hotter with longer stickout.

-

-

However

there is a reduction in weld penetration when varying stickout in a normal range

from 3/8 to 3/4 inches is 24%! If extended to 7/8 inches penetration

decreases 29%.

Therefore it is

very important to keep the torch stickout constant. Also the shorter the

distance from tip to work for a fixed wire feed speed the greater the

penetration since current also increases. When welding in the short

circuiting mode it is often desirable to use a long contact tip

which

protrudes from the shielding gas cup. This helps assure adequate

penetration is maintained by keeping current higher. It also helps

visibility so the welder can stay on the leading edge of the weld puddle.

The picture

right is from our recently published book and is one of several examples

presented of the effects of MIG welding parameter changes on weld performance.

See Book Details on Current

Speicals Offers Page

|

|

Weld Penetration

Definition

For the purposes of this exercise, weld penetration is a measure of how deep the

weld penetrates in a bead-on-plate deposit. Have a different wire than the 0.035

inch solid wire used in this example? No problem. In fact not only

changes in wire type and size but also shielding gas and torch angle will alter

the actual value. You can generate your own constant K for what you are

doing by making a bead-on-plate deposit, cutting a cross section and etching it.

|

|

Caution About the Use of This

Approach

The above equations are designed to work within a practical range for normal

MIG welding. There are much more elaborate equations that take into

account the variable resistively of material with temperature, other arc effects

etc. However within a range of normal operation the above approach will

work adequately. As mentioned, you may need to develop your own

coefficients. Make a weld, measure the depth of penetration and work

backwards! That is what Clarence Jackson did with thousands of data

points!

Reference (1): AWS Welding Handbook, Volume 1, 9th Addition; pp 79

Reference (2): “The Science of Arc Welding” by C. E. Jackson. 1960 Welding

Journal 39(4) pp 129-s thru 230-s

========== =========== ==========

|

|

|

Book:

"Advanced Automotive Welding"

Author: Jerry Uttrachi

(President of WA Technology)

Great book for welding students to also learn some welding math and

science.

CLICK for Book Details |

Download

PDF Overview of the Book with Contents Page and Several Pictures from Each

Chapter. Download

PDF Overview of the Book with Contents Page and Several Pictures from Each

Chapter. |

|

Review by Editors of Hemmings Motor News; August

2012

"Advanced Automotive Welding" by

Jerry Uttrachi

Welding is a hot topic in the hobby these days. For less than $500 a

do-it-yourselfer can purchase a good quality welder and start laying beads

or zapping in spot welds.

This kind of accessibility to a once specialized skill is excellent for the

hobby, and we encourage everyone with an interest to learn to weld. Just as

important as buying the gear, however, is getting versed in the many

different processes, techniques and materials used in all types of welding.

A class at a local welding school or a community college is a good place to

start, as is the purchase of a book like Advanced Automotive Welding, part

of Car Tech’s SA Design series.

Despite the “Advanced” in the title, the book is a good resource for

beginning and intermediate welders. The author, Jerry Uttrachi, is a former

American Welding Society President, with 40 years of welding experience, as

well as a car enthusiast, and he writes in a clear, mostly jargon free

style.

The book covers all welding processes, as well as cutting processes, and

includes insight into some car related welding projects. Advanced

Automotive welding is a good addition to any budding or experienced metal

worker’s shelf. |

|

========== =========== ==========

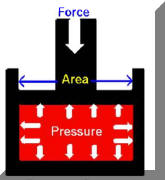

Gas Pressure/Volume Calculations

Understanding

the relationship between gas pressure and volume will help when setting gas

flow and understanding MIG shielding gas use and waste. Understanding

the relationship between gas pressure and volume will help when setting gas

flow and understanding MIG shielding gas use and waste.

In 1662 Robert Boyle defined the basic

relationship between gas Pressure and Volume. He stated the

relationship in mathematic terms as:

P1 / P2 = V1 / V2

(Where P, pressure, is measured as absolute pressure =

gauge pressure + 14.7 psi at sea

level)

For example, in a MIG gas delivery hose if

the initial absolute pressure is doubled the gas volume must be double.

That was until 140 years later when around 1800 both Charles and Dalton

independently added temperature to the relationship! They defined the

following relationship:

V1 / V2

= T1 / T2

(Where T, Temperature is measured as absolute Temperature in degrees Rankin

= Degrees Fahrenheit gauge + 460)

Applying this equation we'll

see in general we need not worry about temperature effecting volume in

normal ranges:

i.e.

V1 / V2

=T1 / T2

If

T1=75

F than T1Rankin

=

75+460=535 R

Assume T2 = T1 +

20% =90 deg F; then T2

Rankin

= 90+460=550 R

V1/V2 due to 20

% Temp Difference =

V1 / V2

=T1 / T2=

535/550=0.97

Or

at a constant pressure, an increase in Temperature of 20% measured in

degrees Fahrenheit yields only 3% increase in volume. For most welding

purposes and over the range of production temperatures there is not enough

change in Volume with gas Temperature to

consider it significant.

The general Gas Laws can

be written as:

(P1 X V1) / T1

= (P2 x V2 ) / T2

It can also be written as P x V = (nR) T

where the constants nR can defined based on

the gas. We'll let you find details about the nR by searching

the Internet since for our purposes ratio comparisons are all we need.

MIG WELDING EXAMPLE

Assume:

-

The pressure needed in the gas delivery

hose from gas source to welder/feeder to flow 30 CFH is 3 psi.

-

A regulator/flowmeter is used that

utilizes an 80 psi regulator.

Therefore when welding stops gas

continues to flow through the needle valve flow control until the

pressure in the gas delivery hose equals 80 psi.

Then the volume of excess gas in the gas

delivery hose compared to the volume when welding will be:

V

stopped / V

welding

=

P

stopped / P

welding

=

(80

psi +15) / (3 psi + 15) = 5.3 times the physical hose

volume

Hose

Expansion Causes More Excess Volume: Tests of a standard 1/4 inch diameter gas

delivery hose showed it had a 13%

increased volume due to the hose expanding with 80 psi pressure.

Therefore 87% of the excess gas stored in the hose is

due to the increased Pressure and 13% of the excess due to Hose Expansion.

SEE MORE DETAILS.

Excess Gas

Blasts Out of the MIG

Torch When Welding Starts: The high velocity creates turbulence in

the shielding gas stream which takes several seconds to stabilize to a

desirable smooth Laminar flow. The turbulence pulls in air

causing excess

spatter and internal weld porosity. For a typical 5/8 inch diameter MIG

nozzle more than 50 CFH flow rate causes this turbulent flow. For

a smaller 1/2 inch diameter nozzle flow rates should not exceed about 40 CFH. |

|

Was This Welding Math Information Useful? What Other Math Would You Like

To See?

|

|

F REE

Technical Paper Available Entitled; "MIG Shielding Gas Control and Optimization"

(or Everything You Didn't Know You

Needed to Ask About MIG Shielding Gas Control!) It Summarizes Key points

in this Web Site and numerous Technical Presentations made in US and

International Welding Conferences about the gas REE

Technical Paper Available Entitled; "MIG Shielding Gas Control and Optimization"

(or Everything You Didn't Know You

Needed to Ask About MIG Shielding Gas Control!) It Summarizes Key points

in this Web Site and numerous Technical Presentations made in US and

International Welding Conferences about the gas shielding problems and solutions.

shielding problems and solutions.

CLICK ICON to

Download PDF DOWNLOAD

|

|

Testimonials from Teachers About Our Welding Math

Information |

|

Email 1:

Brad Weaver,

Science Teacher

Belmont Career and Technical Education Center Sent This Email Requesting:

"..permission to use the wonderful materials you have produced on welding

math and physics with the students here at our career and technical

education center. As the science teacher at the center, I am always looking

for ways to instruct key science and math concepts and skills in the context

of the technical programs. When the lesson materials come from their field

of study, it is more meaningful to the students for the direct application

of science and math. In searching for materials on instruction regarding the

use of the ruler, I came across your website, and shared it with our welding

instructor, Mr. Greg Hutchison." We would like to incorporate your

materials into our lessons."

We Thanked Brad and Gave Permission

|

|

Email 2:

Mrs. Vicki S. Morrow, a Mathematics Teacher Asked:

“Would it be possible for me to print out and share your

welding math information with a specific student? He attends my school

part-time and a trade school the remainder of the time. I thought I could

make math more relatable to him because he is studying welding and is very

interested in the subject. I really appreciate the information available on

your site."

After providing permission she emailed and said:

"Thank you so much. Your site is perfect for what I need for my student." |

|

See YouTube Video Discussion of Our

Patented Shielding Gas Saver System

Also shows some Bernoulli gas equations

CLICK HERE OR PIC OF

OUR STREET ROD |

|

See

"Welding; Go Green" Video

CLICK Here or Picture Left

Shows Calculation

of How Industrial MIG Welders Waste 8 TONS/YEAR of CO2

(or Argon) Shielding Gas

|

See YouTube Video Discussion of

"Welding Race Cars" with Video Clips of

Richard Petty Discussing Importance of

Welding

CLICK HERE OR PIC OF

NASCAR CHASSIS |

Calculate Weld Metal Volume for

Any Weld Joint.

Also Calculate Amount of Rod or

Wire Needed to Fill the Weld. Joint. Click

Here or ICON. |

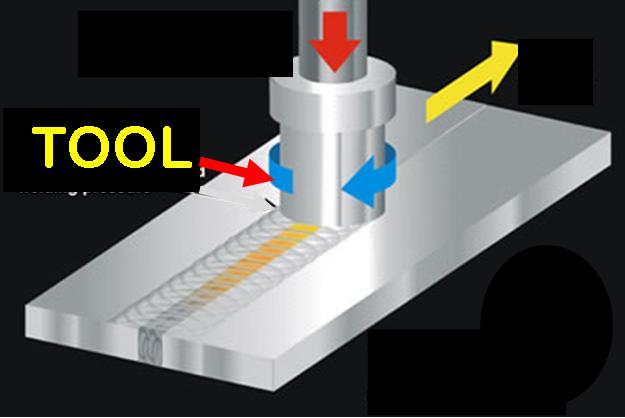

New Info-"Friction

Stir Welding" |

Some

additional gas physics you might find interesting was learned from a scientist,

Evangelista Torricelli, who explained the effects of a vacuum in 1643.

He solved a puzzle at the time of why irrigation and mine water pumps could

only lift water 33 feet. He also invented the Barometer (his apparatus

right.)

CHECK

IT OUT Some

additional gas physics you might find interesting was learned from a scientist,

Evangelista Torricelli, who explained the effects of a vacuum in 1643.

He solved a puzzle at the time of why irrigation and mine water pumps could

only lift water 33 feet. He also invented the Barometer (his apparatus

right.)

CHECK

IT OUT |

Want

to know how to calculate weld cooling rate? The equations for

calculating cooling rates in thick and thin material are presented under

"Welding 4130." Cooling rates are very important to understand for

4130. However the equations can be used for any material.

CHECK IT OUT Want

to know how to calculate weld cooling rate? The equations for

calculating cooling rates in thick and thin material are presented under

"Welding 4130." Cooling rates are very important to understand for

4130. However the equations can be used for any material.

CHECK IT OUT |

Improve MIG Weld Starts

and Have Shielding Gas Cylinder Last 2 to 3 Times Longer! Click Here.

Ideal for Welding Schools

CLICK FOR DETAILS

A small shop fabricator

in Georgia with a Miller TM 175 amp welder

purchased a 50 foot Gas Saver System so he could use a larger cylinder

and mount it on the wall of his shop. He wrote:

"The system works great.

Thanks for the professional

service and a great

product."

CHECK OUT HIS SHOP

|

|

Purchase Flow Rate Limiter |

Purchase

Gas Saving

Products |

|

|

|

Purchase

Training

Products |

Purchase Wire Feeding Aids |

|

| |

|

Purchase Replaceable Orifice Flow Control System |

|